- AUTOMATION EQUIPMENT

- BURNER CONTROL

- CAPACITOR

- CARD ENCODERS & READERS

- CONTROL VALVE

- CONTROLLER

- CONTROLS

- CONVERTER

- DRAIN CLEANING MACHINES & TOOLS

- ELECTRIC EQUIPMENT

- ELECTRICAL ITEMS

- FLOW METERS

- GAS DETECTORS & MONITORS

- GENERAL PURPOSE AC DRIVE

- GRAPHOMETER

- HVAC & REFRIGERATION PRESSURE SWITCHES

- HYDRAULIC PRESS

- INK RIBBONS

- LEAK DETECOTR

- LIMIT SWITCH

- METER

- OTHER AIR COMPRESSORS

- PANEL METERS

- POWER MODULE

- SAFTY EQUIPMENT

- SERVO DRIVES & AMPLIFIERS

- TACHOMETER

- TEMPERATURE COMPENSATING

- UNCATEGORIZED

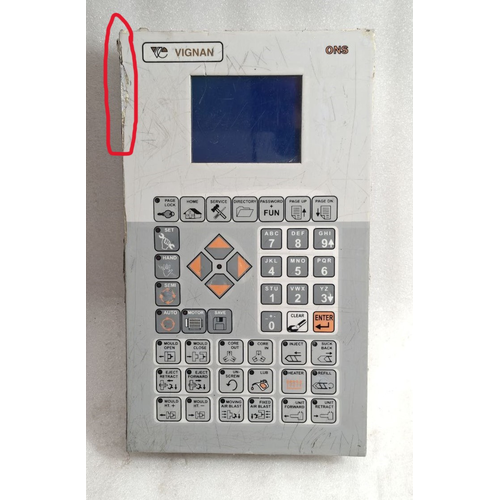

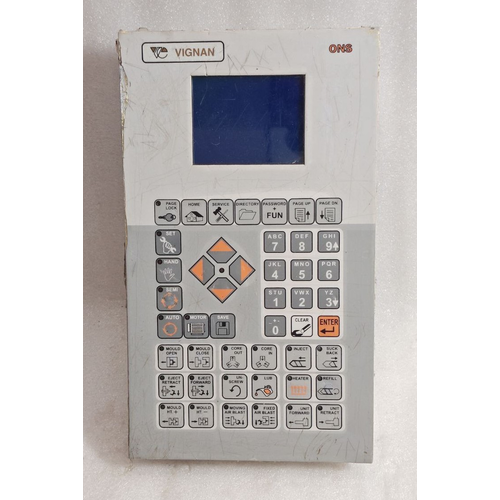

VIGNAN ONS INJECTION MOULDING MACHINE CONTROLLER ONS 13:22

$499.99

| Product Conditioned | USED |

|---|

In simple terms, this is the “brain box” for a specific brand of plastic moulding machine.

It’s the computer that tells the machine how to make plastic parts—how hot to get, how much pressure to use, and when to open and close the mould. You wouldn’t buy this unless you own the exact model of Vignan machine that it came from and your current controller is broken. It’s a highly specific spare part for a manufacturing plant, not a general-purpose item. Buying it used is a gamble unless you can test it immediately, as configuring it likely requires factory-level expertise.

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

The Vignan ONS is a specialized Programmable Logic Controller (PLC) or dedicated microprocessor-based controller designed specifically for the automation and operation of injection moulding machines. It is the central “brain” that controls every aspect of the moulding process, from injecting plastic into a mould to ejecting the finished part.

Key Features & Specifications

-

Manufacturer: Vignan (An Indian company known for manufacturing injection moulding machines and their control systems). The “ONS” is likely their model series for a controller.

-

Type: Industrial Machine Controller. This is not a general-purpose PLC; it is highly specialized hardware and software built for one task.

-

Core Function: To automate the complex cycle of an injection moulding machine. This includes controlling:

-

Injection Unit: Screw rotation, injection speed and pressure, holding pressure.

-

Clamping Unit: Mold open/close, clamping force, ejector operation.

-

Temperature Control: Precise PID control of multiple heating zones on the barrel and the mould.

-

Timers & Counters: Managing cycle times, shot counts, and production quotas.

-

-

User Interface: The controller would typically pair with a separate operator panel (often a touchscreen or keypad with a display) that allows the operator to input recipes (setpoints for temperature, pressure, time, position) and monitor the machine’s status.

-

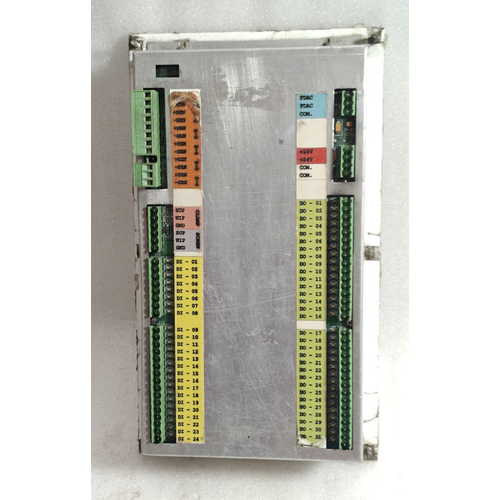

Inputs/Outputs (I/O): It has numerous connections for:

-

Inputs: Sensors (temperature, pressure, position, limit switches).

-

Outputs: Actuators (solenoid valves for hydraulic functions, motors, heaters, alarms).

-

What is it used for? (Purpose)

This controller is used to:

-

Automate Production: Run complex injection moulding cycles repeatedly with high precision and consistency.

-

Ensure Quality: Maintain exact parameters (temperature, pressure, speed) to produce identical plastic parts every cycle.

-

Monitor Machine Health: Provide diagnostics and alarm messages for faults (e.g., overheating, low pressure, motor failure).

-

Store Recipes: Save settings for different products/moulds, allowing for quick changeovers.

Who is this for? (Ideal User)

This is an extremely specialized component for:

-

Industrial Maintenance Technicians and Engineers who work specifically on Vignan brand injection moulding machines.

-

The Owner of a Vignan ONS Injection Moulding Machine with a faulty controller who needs a direct replacement.

-

Automation Specialists with deep knowledge of legacy machine controls (though a machine-specific controller is less universal than a standard PLC).

Critical Considerations for a “USED” Unit

-

Absolute Compatibility: This controller will only work with the specific model of Vignan injection moulding machine it was designed for. It is not a universal part.

-

Configuration/Software: It likely contains machine-specific firmware and parameters. A used unit may need to be reprogrammed with the correct machine software and calibrated, which requires specialized knowledge and software tools from Vignan.

-

Unknown History: As a used electronic component from a harsh industrial environment (with heat, vibration, and potential hydraulic fluid leaks), its reliability is not guaranteed. Components can be degraded.

-

I/O Modules: The controller may consist of a central processing unit and several additional I/O modules. The listing must be checked to confirm what is included.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.