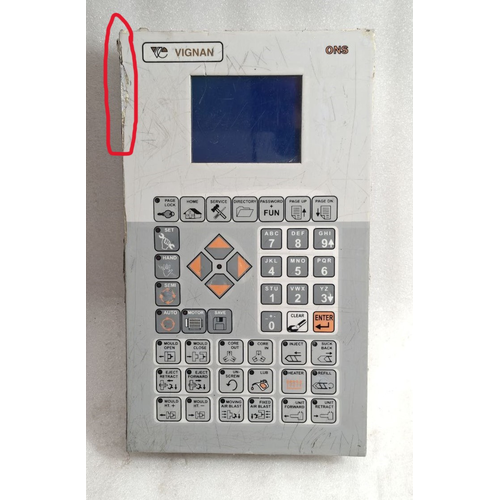

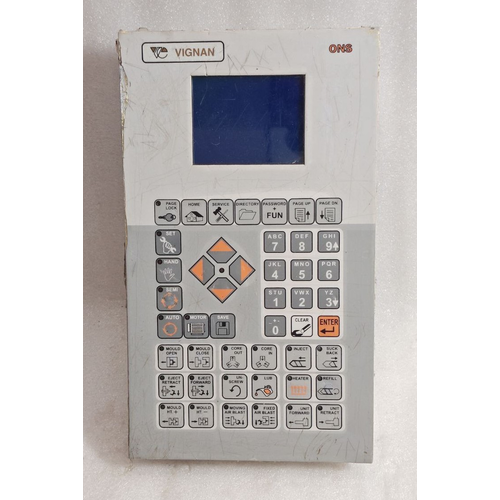

The Vignan ONS is a specialized Programmable Logic Controller (PLC) or dedicated microprocessor-based controller designed specifically for the automation and operation of injection moulding machines. It is the central “brain” that controls every aspect of the moulding process, from injecting plastic into a mould to ejecting the finished part.

Key Features & Specifications

-

Manufacturer: Vignan (An Indian company known for manufacturing injection moulding machines and their control systems). The “ONS” is likely their model series for a controller.

-

Type: Industrial Machine Controller. This is not a general-purpose PLC; it is highly specialized hardware and software built for one task.

-

Core Function: To automate the complex cycle of an injection moulding machine. This includes controlling:

-

Injection Unit: Screw rotation, injection speed and pressure, holding pressure.

-

Clamping Unit: Mold open/close, clamping force, ejector operation.

-

Temperature Control: Precise PID control of multiple heating zones on the barrel and the mould.

-

Timers & Counters: Managing cycle times, shot counts, and production quotas.

-

-

User Interface: The controller would typically pair with a separate operator panel (often a touchscreen or keypad with a display) that allows the operator to input recipes (setpoints for temperature, pressure, time, position) and monitor the machine’s status.

-

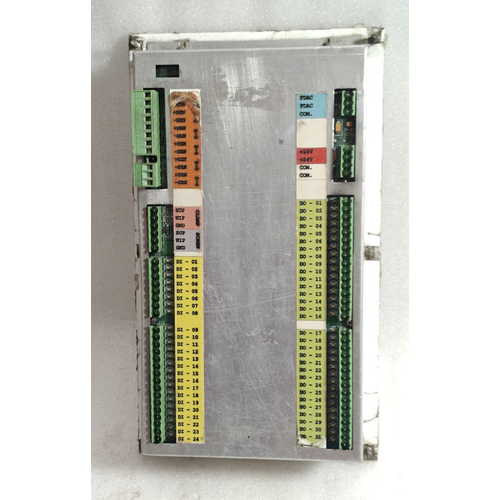

Inputs/Outputs (I/O): It has numerous connections for:

-

Inputs: Sensors (temperature, pressure, position, limit switches).

-

Outputs: Actuators (solenoid valves for hydraulic functions, motors, heaters, alarms).

-

What is it used for? (Purpose)

This controller is used to:

-

Automate Production: Run complex injection moulding cycles repeatedly with high precision and consistency.

-

Ensure Quality: Maintain exact parameters (temperature, pressure, speed) to produce identical plastic parts every cycle.

-

Monitor Machine Health: Provide diagnostics and alarm messages for faults (e.g., overheating, low pressure, motor failure).

-

Store Recipes: Save settings for different products/moulds, allowing for quick changeovers.

Who is this for? (Ideal User)

This is an extremely specialized component for:

-

Industrial Maintenance Technicians and Engineers who work specifically on Vignan brand injection moulding machines.

-

The Owner of a Vignan ONS Injection Moulding Machine with a faulty controller who needs a direct replacement.

-

Automation Specialists with deep knowledge of legacy machine controls (though a machine-specific controller is less universal than a standard PLC).

Critical Considerations for a “USED” Unit

-

Absolute Compatibility: This controller will only work with the specific model of Vignan injection moulding machine it was designed for. It is not a universal part.

-

Configuration/Software: It likely contains machine-specific firmware and parameters. A used unit may need to be reprogrammed with the correct machine software and calibrated, which requires specialized knowledge and software tools from Vignan.

-

Unknown History: As a used electronic component from a harsh industrial environment (with heat, vibration, and potential hydraulic fluid leaks), its reliability is not guaranteed. Components can be degraded.

-

I/O Modules: The controller may consist of a central processing unit and several additional I/O modules. The listing must be checked to confirm what is included.