- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- SENSORS

- UNCATEGORIZED

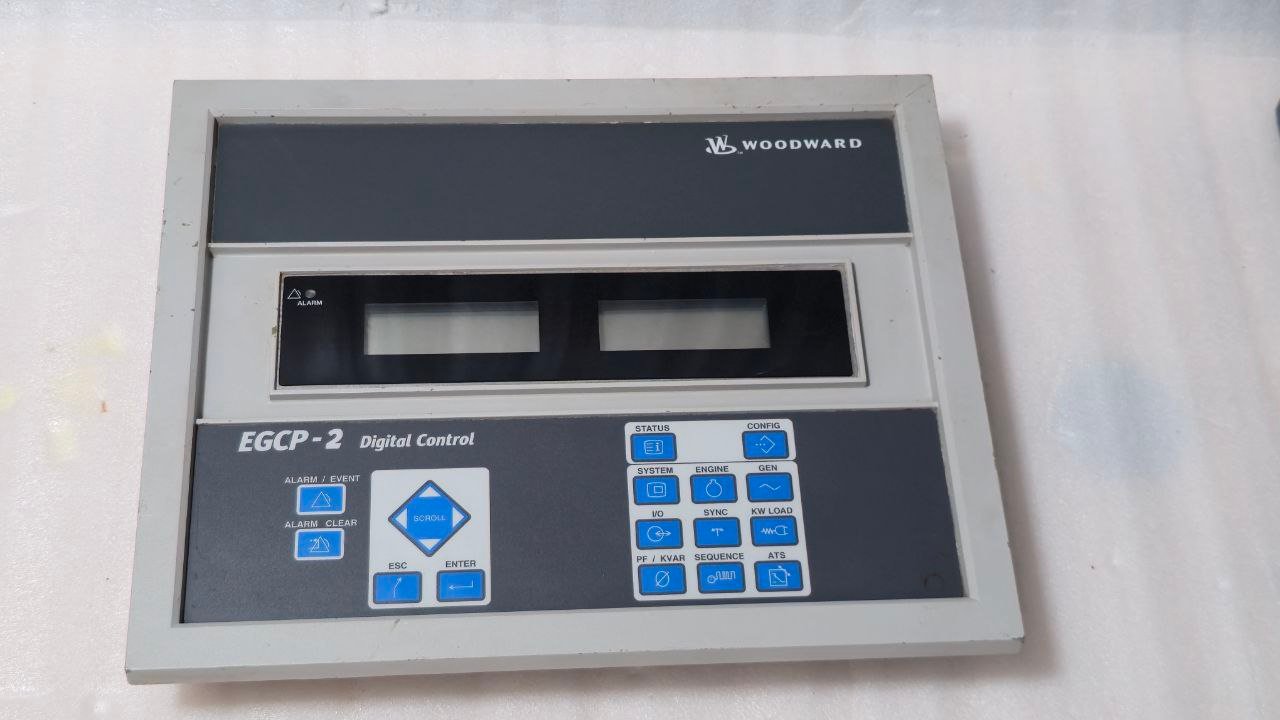

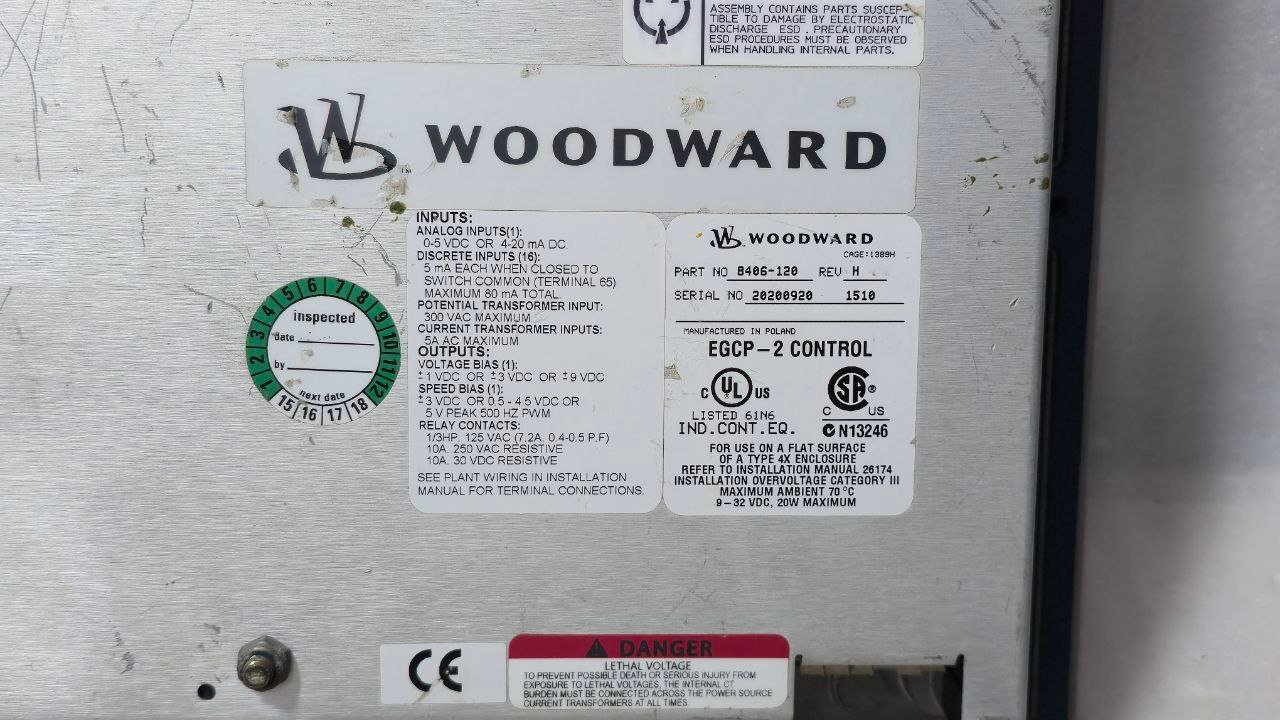

WOODWARD EGCP-2 ENGINE DIGITAL CONTROL PART NO-8406 120 REV H 17:24

$750.00

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

The Woodward EGCP-2 is a sophisticated, microprocessor-based digital control system designed primarily for managing and protecting standby and prime power generator sets. The part number 8406-120 Rev H refers to a specific configuration of the hardware and firmware for this controller.

It serves as the central “brain” of a generator set, integrating engine control, generator control, and synchronizing/paralleling functions into a single, compact unit.

Key Functions and Features

The EGCP-2 is known for its robust feature set, which includes:

1. Engine Control and Protection:

-

Governing: Precise speed control (RPM) of the engine via a electronic governor actuator or electric fuel control.

-

Start/Stop Sequencing: Automatically controls the cranking, purging, and start/stop cycles of the engine.

-

Engine Protection: Monitors critical engine parameters (coolant temperature, oil pressure, engine overspeed) and will alarm or shut down the generator set to prevent catastrophic damage.

-

Analog and Digital I/O: Multiple inputs and outputs for connecting sensors (temperature, pressure) and controlling devices (starter contactors, fuel solenoids).

2. Generator Control and Protection:

-

Voltage Regulation: Maintains a stable generator output voltage under varying load conditions.

-

Generator Protection: Monitors electrical parameters and provides protection against faults such as:

-

Overvoltage / Undervoltage

-

Overfrequency / Underfrequency

-

Overcurrent

-

Loss of Mains (if configured)

-

3. Synchronizing and Paralleling (A Core Feature):

-

Synchronization: The EGCP-2 can automatically synchronize the generator to another generator or to the utility mains. It matches the voltage, frequency, and phase angle before closing the generator breaker.

-

Isochronous Load Sharing: When multiple generator sets are running in parallel, the EGCP-2 works with other EGCP-2 units (or compatible Woodward controls) to ensure all units share the total electrical load proportionally.

-

Droop Operation: Also supports droop mode for load sharing with utility mains or other specific applications.

4. Human-Machine Interface (HMI):

-

The unit features a backlit LCD display and a keypad for local operation and configuration.

-

It provides real-time data display (volts, amps, frequency, kW, etc.), alarm/status messages, and menu-driven setup.

5. Communications:

-

The standard communication protocol for the EGCP-2 is Modbus RTU via an RS-485 serial port. This allows for integration into larger Building Management Systems (BMS) or SCADA systems.

-

An optional communication card (like the 9907-XXX series) could be added for other protocols like Profibus, DeviceNet, or Ethernet.

Typical Applications

The EGCP-2 is commonly found in:

-

Standby Power Generators: For commercial buildings, data centers, hospitals, and other critical facilities.

-

Prime Power Generators: In remote locations or industrial sites where the generator is the primary source of power.

-

Peak Shaving Systems: To generate power during periods of high utility demand.

-

Base Load Power Plants: Multiple units operating in parallel.

-

Marine Applications.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.