- AUTOMATION EQUIPMENT

- BURNER CONTROL

- CAPACITOR

- CARD ENCODERS & READERS

- CONTROL VALVE

- CONTROLLER

- CONTROLS

- CONVERTER

- DRAIN CLEANING MACHINES & TOOLS

- ELECTRIC EQUIPMENT

- ELECTRICAL ITEMS

- FLOW METERS

- GAS DETECTORS & MONITORS

- GENERAL PURPOSE AC DRIVE

- GRAPHOMETER

- HVAC & REFRIGERATION PRESSURE SWITCHES

- HYDRAULIC PRESS

- INK RIBBONS

- LEAK DETECOTR

- LIMIT SWITCH

- METER

- OTHER AIR COMPRESSORS

- PANEL METERS

- POWER MODULE

- SAFTY EQUIPMENT

- SERVO DRIVES & AMPLIFIERS

- TACHOMETER

- TEMPERATURE COMPENSATING

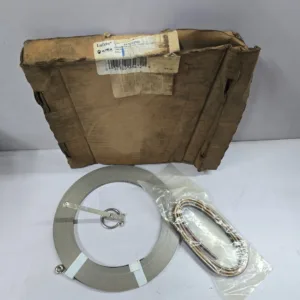

- UNCATEGORIZED

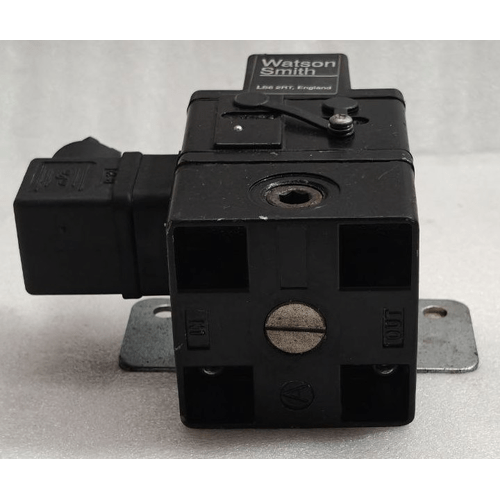

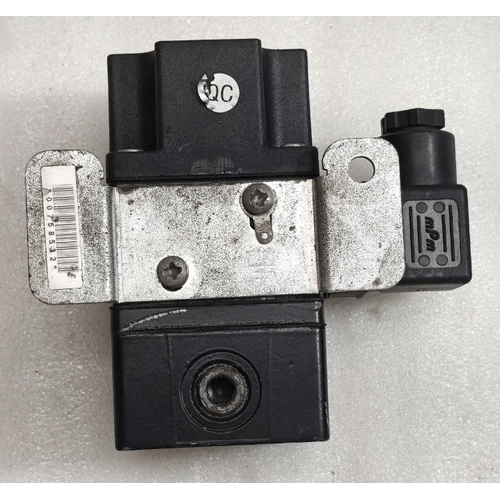

WATSON SMITH LS6 2RT PNEUMATIC PRESSURE REGULATOR 402100R CONVERTER TYPE 100X 12:40

$99.00

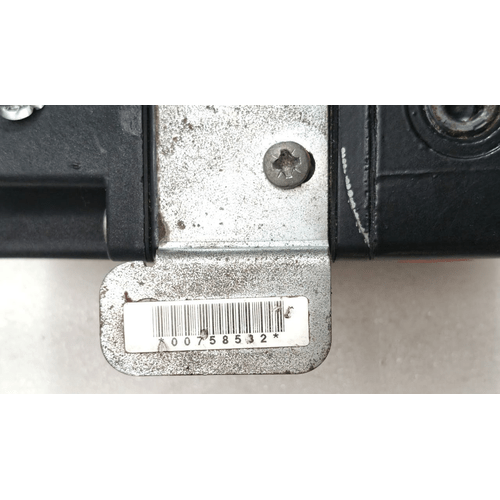

| Product Conditioned | USED |

|---|

The Watson Smith LS6 2RT Type 100X is a precision I/P (Current-to-Pressure) converter. It is a fundamental component in process automation, acting as a translator that takes a 4-20 mA electrical command from a controller and converts it into a precise, proportional air pressure to operate pneumatic equipment.

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

1. Product Name & Model:

-

Manufacturer: Watson Smith (A renowned British manufacturer of highly reliable pneumatic and process control instrumentation, now part of the IMI Precision Engineering group).

-

Product Line/Model: LS6 2RT

-

Function: Pneumatic Pressure Regulator and Converter (Specifically, an I/P (Current-to-Pressure) Converter).

-

Sub-type / Variant: Type 100X

-

Part Number: 402100R (This is likely a specific part or kit number for this variant).

2. Key Features & Functionality:

-

Core Purpose: This device is an I/P Converter (Current-to-Pressure). It converts a standard electrical control signal into a precise pneumatic output pressure.

-

Input (I): It receives an analog current signal, typically 4-20 mA, from a process controller, PLC, or control system.

-

Output (P): It provides a regulated pneumatic output pressure that is directly proportional to the input current signal. A common output range is 3-15 psi (or 0.2-1.0 bar), which is the standard signal for pneumatic actuators.

-

-

“Pneumatic Pressure Regulator”: This name refers to its function of very accurately regulating its output air pressure based on the electrical command signal.

-

Design: The LS6 series is known for its robust, industrial-grade design. The “2RT” likely specifies the port sizes (e.g., 1/4″ BSP) and the specific output range.

-

Type 100X: This designation differentiates it from other models in the LS6 line, likely indicating specific internal components, performance specifications, or materials.

3. Technical Specifications (Inferred from Standard LS6 Models):

-

Supply Pressure: Requires a clean, dry air supply at a pressure higher than the desired output (e.g., 20-30 psi / 1.4-2.0 bar supply for a 3-15 psi output).

-

Input Signal: 4-20 mA DC (standard for process control).

-

Output Pressure: Likely a standard range like 3-15 psi or 0.2-1.0 bar.

-

Accuracy: Watson Smith regulators are known for high accuracy and reliability.

-

Construction: Typically made from brass or stainless steel for corrosion resistance in industrial environments.

4. Intended Use & Context:

This is a critical component in automated industrial control systems, used to interface between electronic control systems and pneumatic actuators. Common applications include:

-

Controlling the position of pneumatic valve actuators in process plants (chemical, oil & gas, power generation, water treatment).

-

Operating pneumatic diaphragms, cylinders, and other devices based on an electrical signal.

-

Used wherever a computer or PLC needs to precisely control a pneumatic process.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.