- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

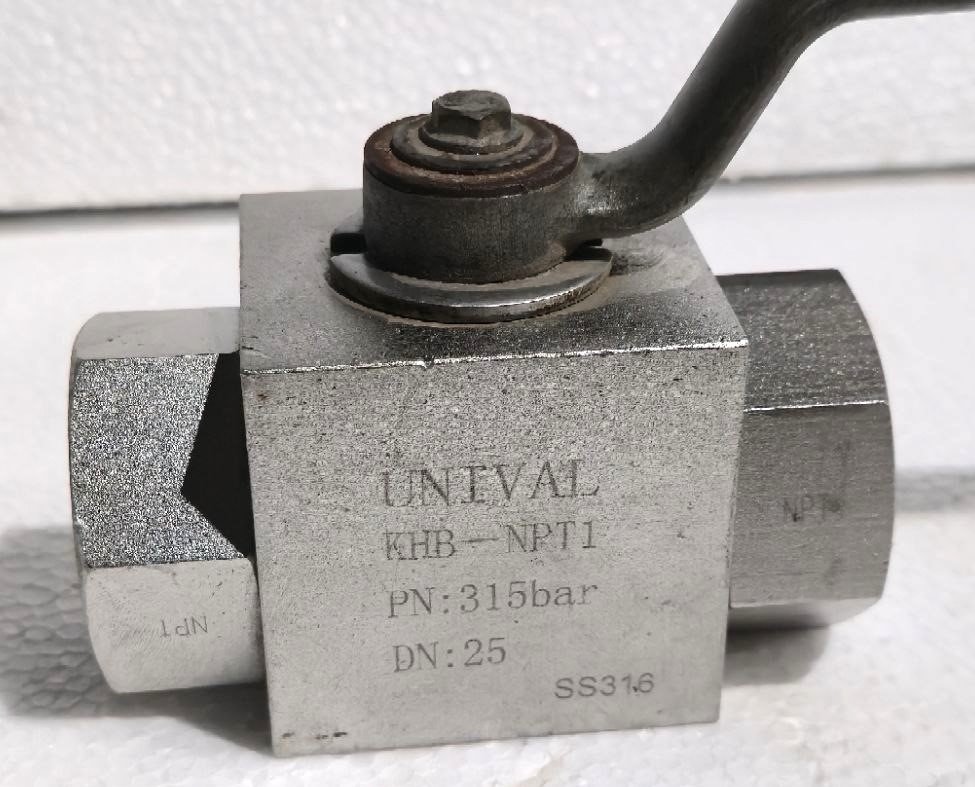

UNIVAL HYDRAULIC SHUTOFF HIGH PRESSURE BALL VALVE KHB-NPT1 315BAR DN25 15:56

₹0.00

| Product Conditioned | NEW |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

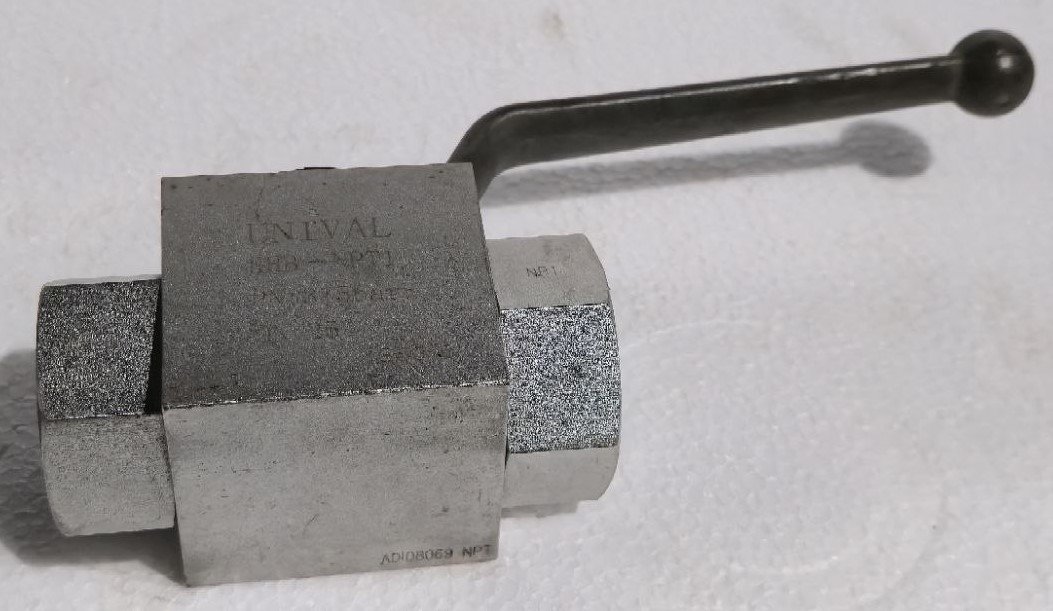

The UNIVAL KHB-NPT1 is a robust, two-way shut-off ball valve engineered specifically for demanding high-pressure hydraulic and industrial fluid applications. Its primary function is to provide a positive, bubble-tight seal to completely isolate sections of a circuit for maintenance, safety, or system configuration. The “KHB” series typically denotes a compact, forged body design for maximum strength and reliability under extreme pressure.

Key Specifications & Code Breakdown

-

KHB: Likely the series/model code, indicating a specific design (forged body, specific seal package).

-

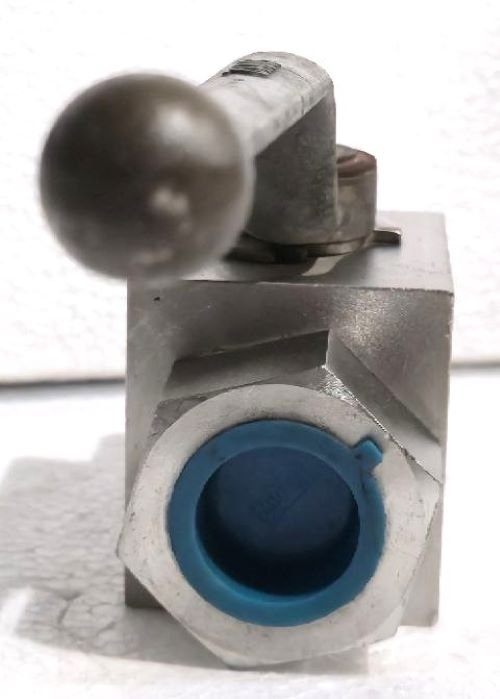

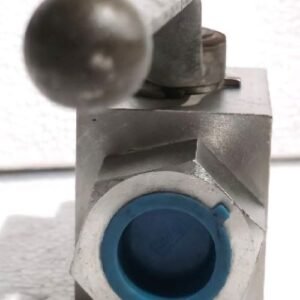

NPT1: Connection Type – NPT (National Pipe Taper) thread. The “1” commonly refers to a female (F) port thread on both ends. This is the standard connection for North American fluid power systems.

-

315BAR: Maximum Working Pressure – 315 Bar (approximately 4,570 PSI). This high rating makes it suitable for heavy-duty hydraulic systems in construction, mining, agriculture, and industrial machinery.

-

DN25: Nominal Diameter – 25mm, which corresponds to a 1 inch NPT connection. This indicates the nominal flow path size.

Key Features & Design

-

Forged Body Construction: Typically made from high-tensile carbon steel, providing exceptional strength and resistance to pressure surges and mechanical shock.

-

Ball Valve Mechanism: A chrome-plated or stainless steel ball with a precision mirror finish ensures smooth operation and a reliable, low-torque seal. The quarter-turn (90-degree) operation allows for quick and easy open/close control.

-

High-Pressure Seals: Utilizes advanced seal materials (such as Polyurethane, NBR, or other engineered polymers) compatible with a wide range of hydraulic fluids (mineral oil, HFA/HFB, water-glycol) and resistant to high pressure and extrusion.

-

Robust Stem & Seal Design: Features a blow-out-proof stem to prevent stem ejection under pressure. Multiple stem seals ensure long-term leak-free performance.

-

Handle/Actuator: Equipped with a color-coded (often red) locking handle. The handle can be locked in the OPEN or CLOSED position with a padlock for safety (Lockout/Tagout – LOTO procedures).

-

Compact Design: Designed for easy installation in tight spaces within machine manifolds or line layouts.

-

Surface Treatment: Body is usually phosphate-coated and painted for corrosion resistance. Active parts may be zinc or chrome-plated.

Typical Applications

-

Isolation valves on hydraulic cylinders, pumps, motors, and accumulators.

-

Manifold and valve bank isolation.

-

Maintenance shut-off points in mobile equipment (excavators, loaders, cranes).

-

Industrial hydraulic power units (HPUs) and test stands.

-

Any application requiring a reliable, high-pressure, positive shut-off valve.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.