- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

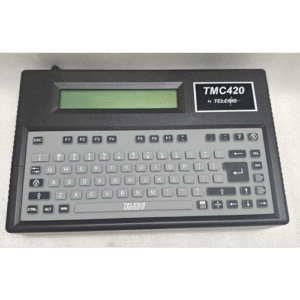

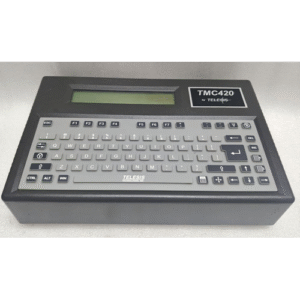

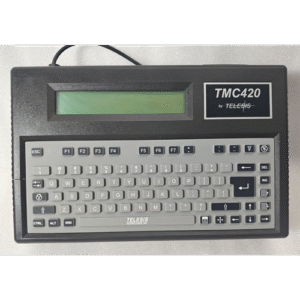

TELESIS TMC420 MARKING SYSTEM CONTROLLER 115/230V 10:58

$420.00

| Product Conditioned | Not Working For Parts Only |

|---|

The Telesis TMC-420 is a versatile, industrial-grade controller that serves as the brains behind an automated permanent part marking system. It is a critical component for adding traceability marks to parts in a high-volume manufacturing environment and must be matched with a compatible Telesis marking head.

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

The TELESIS TMC-420 is an industrial Marking System Controller. It serves as the central command unit for operating and controlling an integrated marking system, such as an air-powered pin stamping machine or a dot peen marking system.

This controller takes user input (often from a keypad or a connected computer) and translates it into precise electrical signals that drive the marking head, controlling the movement of the pins or stylus to create alphanumeric codes, serial numbers, logos, and other marks on metal, plastic, or other surfaces.

The “115/230V” rating indicates it can be configured to operate on standard North American (115V) or European/International (230V) AC power.

Key Specifications from the Label

-

Manufacturer: TELESIS (A leading U.S. brand in permanent part marking systems)

-

Model: TMC-420 (Telesis Marking Controller)

-

Component Type: Marking System Controller

-

Input Power: 115/230V AC (Configurable for either voltage, likely via an internal switch or jumper)

-

Condition: Likely used or refurbished, given the context of previous listings.

Key Features and Functions

-

System Brain: Contains the firmware and processing power to generate character strings, logos, and sequential serial numbers.

-

User Interface: Typically features an integrated keypad and an LCD screen for standalone operation, allowing for on-the-fly editing of mark data directly at the machine.

-

Input/Output (I/O) Control: Provides input connections for safety interlocks (e.g., door switches, part-in-place sensors) and output signals to control peripherals like part clamps or cycle start lights. This integrates the marker into a larger automated production line.

-

Communication Ports: Usually includes standard communication interfaces such as:

-

RS-232 Serial Port: For connection to a computer for remote control and data transfer.

-

Ethernet: (On some models) for network integration.

-

-

Drive Outputs: Generates the high-power signals required to drive the solenoids in a pin stamp marker or the motors in a dot peen marker to physically create the mark.

-

Memory: Stores multiple mark programs, fonts, and logos internally for quick recall.

Common Applications

This controller is the core of a permanent part marking (PPM) system used for traceability and identification in manufacturing. Applications include:

-

Automotive & Aerospace: Marking VIN numbers, part numbers, and batch codes on components.

-

Medical Device Manufacturing: Etching unique device identifiers (UDIs) on surgical tools and implants.

-

Metalworking & Fabrication: Adding logos, ratings, and serial numbers to tools, pipes, and plates.

-

Electronics: Marking PCBs and components with lot codes and compliance logos.

Important Notes for Operation and Replacement

-

System Component: This is not a standalone device. It is designed to work only with specific Telesis marking heads (e.g., the Telesis Scribe series or pin stamp markers). Compatibility with the marking head is crucial.

-

Configuration: The voltage input (115V or 230V) must be correctly configured before powering on the unit to prevent damage. The method for this is outlined in the user manual.

-

Programming: Creating and editing complex marks often requires understanding the specific Telesis programming syntax or using dedicated software on a connected PC.

-

I/O Integration: For automated use, the controller’s input and output terminals must be correctly wired to the machine’s sensors and actuators.

-

Technical Support: Telesis provides strong technical support and documentation for their controllers. Finding the specific TMC-420 user manual is essential for installation, wiring, and programming.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.