- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

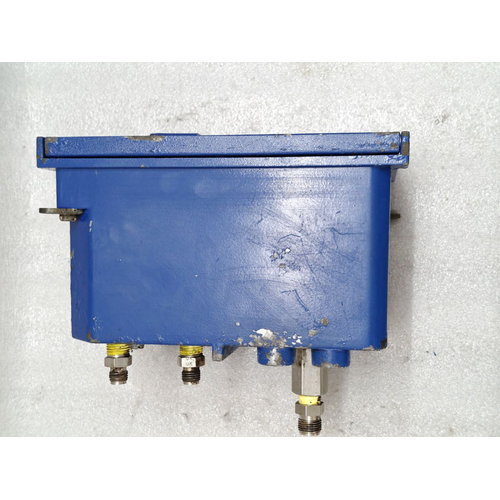

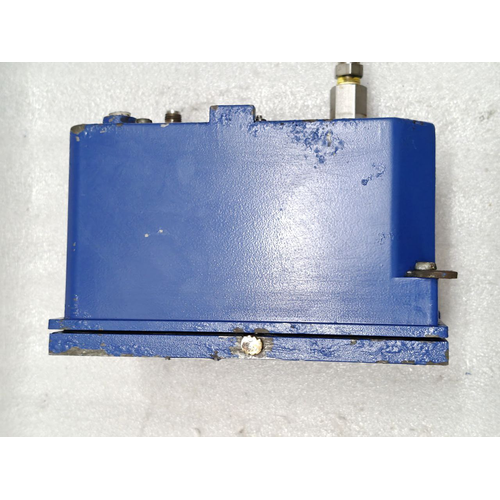

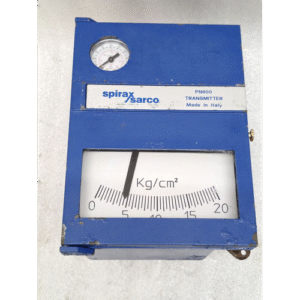

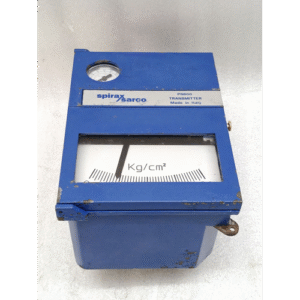

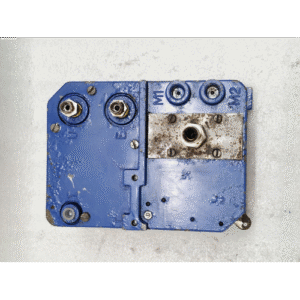

SPIRAX SARCO PN600 KG / CM2 RANGE 0 TO 20 20K0021 625 TRANSMITTER

₹17,805.00

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

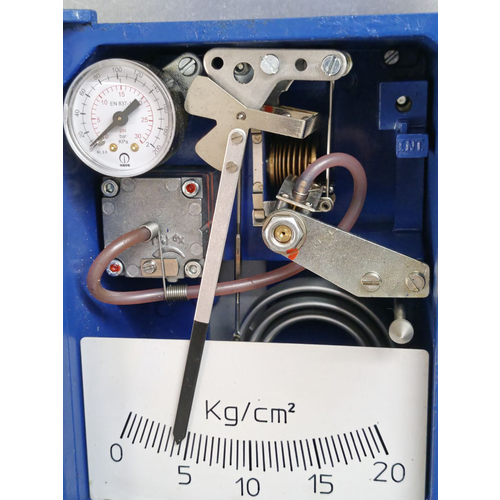

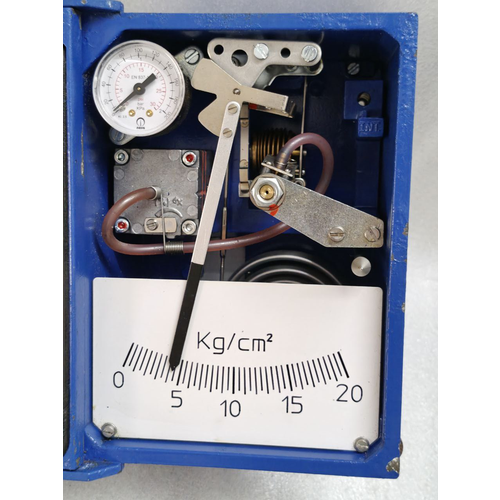

The Spirax Sarco PN600 (20K0021) is a robust and reliable pneumatic pressure transmitter. It is designed to convert a mechanical pressure reading from a pipeline or vessel into a precise, proportional pneumatic output signal. This signal is then transmitted to other devices like controllers, recorders, or indicators for process monitoring and control.

This specific model is part of Spirax Sarco’s extensive range of instrumentation and is known for its durability in demanding industrial environments.

Detailed Specification Breakdown

Let’s break down the information from your query:

-

SPIRAX SARCO: The manufacturer, a world-leading brand in steam system management and industrial fluid control.

-

PN600: The model series. This indicates a pneumatic pressure transmitter designed for general industrial use.

-

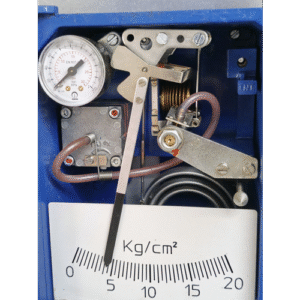

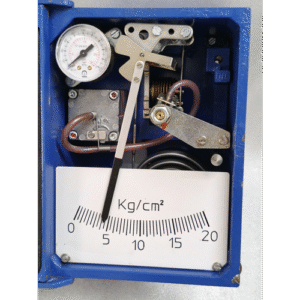

KG / CM²: The unit of measurement for the pressure range. This stands for Kilograms per Square Centimeter.

-

Note:

kg/cm²is effectively equivalent to the metric unitbarfor most practical purposes (1 kg/cm² ≈ 0.980665 bar, but often rounded to 1). It is a common unit in many industrial settings.

-

-

RANGE 0 TO 20: The calibrated measurement range of the transmitter. This device is set to measure pressures from 0 to 20 kg/cm².

-

20K0021: This is the specific Spirax Sarco product code or part number. This unique identifier is used for ordering and technical documentation.

-

625: This is likely a suffix or a code related to a specific variant, connection type (e.g., 1/2″ BSP), body material, or a manufacturing batch code. For precise details, the official datasheet for part number 20K0021 should be consulted.

-

TRANSMITTER: The device category. It transmits a signal representing a measured process variable (in this case, pressure).

-

SEO PRODUCT DESCRIPTION: This suggests the text is intended for an online listing or catalog to help with search engine optimization.

Key Features and Technical Characteristics

Based on the standard design of the PN600 series:

-

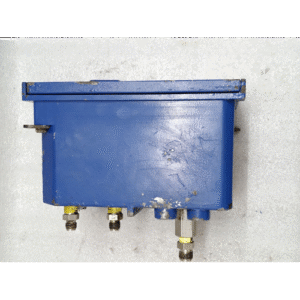

Principle of Operation: It uses a force-balance system. The process pressure acts on a sensing element (like a bourdon tube or diaphragm), and this force is balanced by the output air pressure, creating a proportional relationship.

-

Input Signal: The physical pressure of the process medium (steam, air, water, etc.) from 0 to 20 kg/cm².

-

Output Signal: A standard pneumatic signal, typically 3 to 15 psig (0.2 to 1.0 bar gauge). This is the universal industry standard for pneumatic control systems.

-

Air Supply: Requires a clean, dry compressed air supply for its operation. A typical supply pressure is 20-30 psig (1.4 – 2.0 bar g).

-

Accuracy: Spirax Sarco instruments are known for good accuracy, typically around ±1% of full scale or better.

-

Connections: Features process and air supply connections, likely 1/4″ or 1/2″ BSP (British Standard Pipe) threads, which are very common.

-

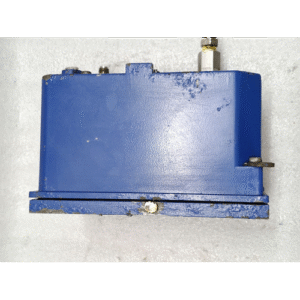

Construction: Built with a durable cast iron or aluminum body, suitable for harsh plant environments.

-

Mounting: Can be directly mounted to a process line or via a manifold.

Typical Applications

This transmitter is used in various industrial processes where pneumatic control is preferred or required, often due to safety (intrinsically safe in hazardous areas) or legacy system compatibility.

-

Steam Systems: Monitoring and controlling steam pressure in boilers, distribution lines, and process equipment.

-

Compressed Air Systems: Regulating and monitoring air pressure in industrial networks.

-

Process Industries: Controlling pressure of various gases and liquids in chemical, pharmaceutical, and food & beverage plants.

-

Heating, Ventilation, and Air Conditioning (HVAC): For control in large building management systems.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.