- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

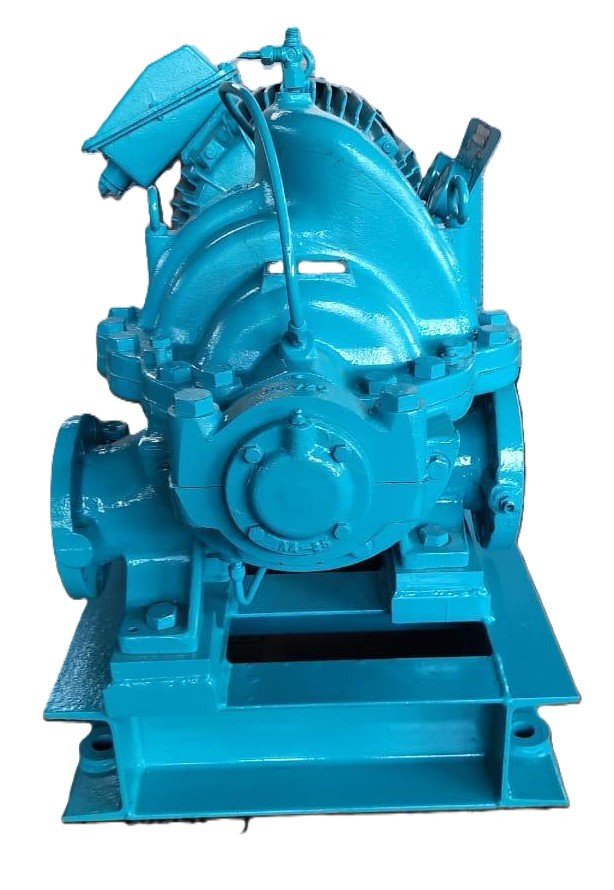

SHINKO GHQ100-2 MARINE PUMP 3-PHASE INDUCTION MOTOR

$0.00

| Product Conditioned | NEW |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

SHINKO GHQ100-2 MARINE PUMP & 3-PHASE INDUCTION MOTOR

Target Keywords & Phrases:

-

Marine centrifugal pump

-

Seawater pump

-

GHQ pump series

-

3-phase induction motor marine

-

Shipboard pump

-

Bilge pump / Ballast pump / Cooling water pump

-

Heavy-duty marine pump

-

Shinko GHQ100-2 specifications

Product Description:

Title: SHINKO GHQ100-2 Marine Centrifugal Pump with 3-Phase Induction Motor | Heavy-Duty Seawater Service

SHINKO GHQ100-2 Marine Centrifugal Pump Unit

Robust & Reliable Performance for Demanding Marine Applications

The SHINKO GHQ100-2 is a high-performance, end-suction centrifugal pump unit designed and built specifically for the harsh conditions of marine and offshore operations. Coupled with a dependable 3-phase AC induction motor, this pump is engineered to handle seawater, bilge water, ballast transfer, general service, and engine cooling water with exceptional durability and efficiency.

Core Product Features & Benefits:

1. Pump Unit (GHQ100-2):

-

Type: Single-stage, end-suction centrifugal pump.

-

Construction: Designed for marine use with materials selected for excellent corrosion resistance (e.g., bronze-fitted, stainless steel, or other specified alloys for impeller, casing, and shaft).

-

Sealing: Equipped with a high-quality mechanical seal or gland packing arrangement suitable for seawater, ensuring long service life and minimal leakage.

-

Design: Compact and robust design for easy installation and maintenance in tight engine rooms or pump rooms.

-

Applications: Ideal for Seawater Cooling, Bilge Pumping, Ballast Transfer, Firefighting Systems, Washdown Services, and General Marine Duty.

2. 3-Phase Induction Motor:

-

Type: Totally Enclosed, Fan-Cooled (TEFC) or drip-proof design as required for marine environment protection.

-

Power & Supply: Designed for standard marine 3-phase AC power supplies (common voltages: 440V/60Hz, 380V/50Hz, etc.). The motor rating is optimally matched to the GHQ100-2 pump performance curve.

-

Construction: Insulation Class (e.g., F or H) for high temperature resistance and reliability. Features anti-corrosion treatment on frames and exterior parts.

-

Reliability: Built to marine standards (such as IEEE, IEC, or specific class society rules) for continuous, trouble-free operation.

3. Key Advantages for Marine Engineers:

-

High Reliability: Minimal downtime due to simple, proven design and quality components.

-

Low Maintenance: Easy access to impeller and seal chamber for inspection and service.

-

Interchangeability: Standardized dimensions and connections facilitate replacement and spare parts procurement.

-

Global Compliance: Can be certified or built to meet major Classification Society requirements (ABS, DNV, LR, etc.) upon request.

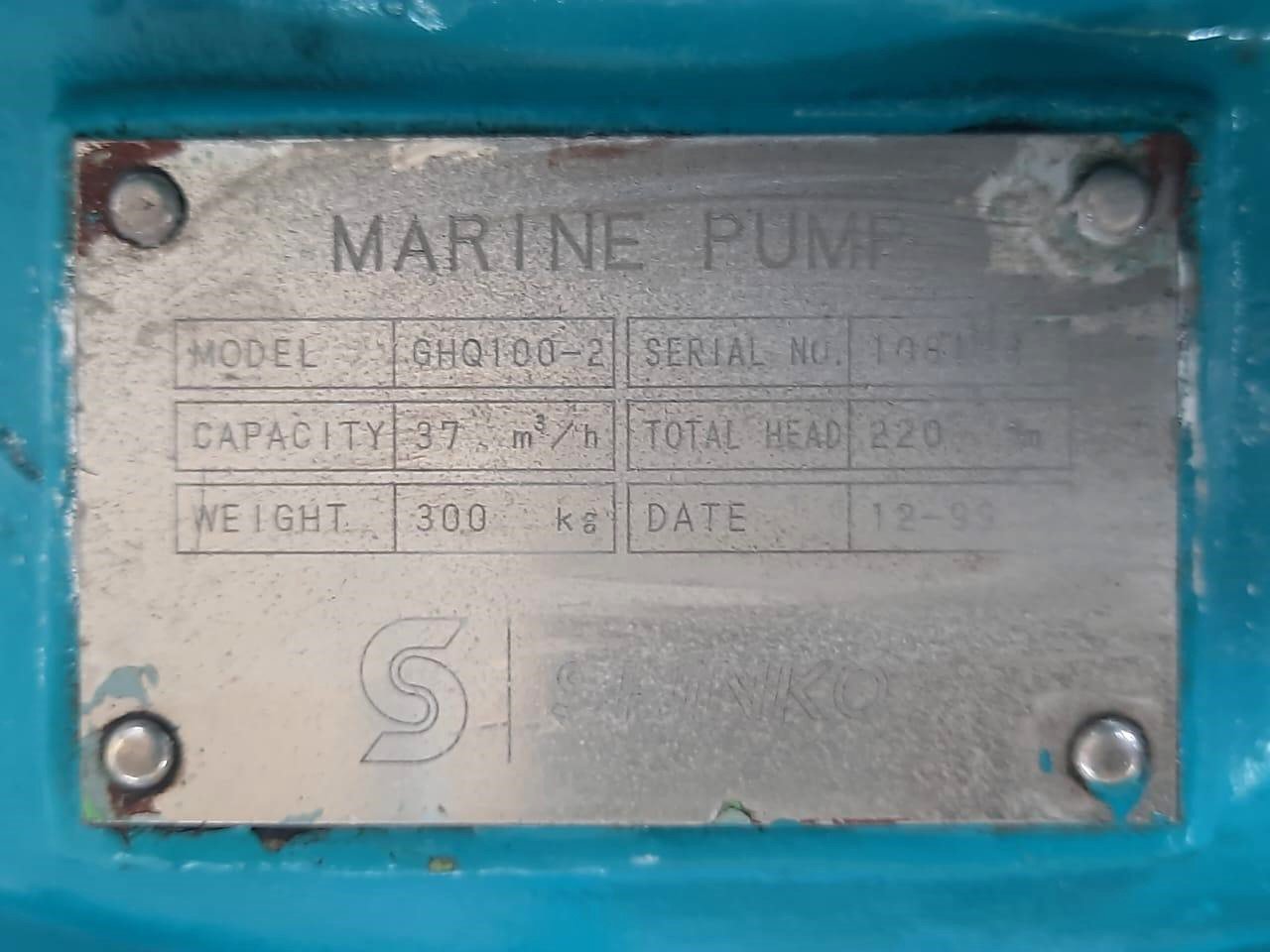

Typical Technical Specifications :

-

Pump Model: GHQ100-2

-

Connection Size: Inlet/Outlet Flange (e.g., 100mm / 4″)

-

Capacity Range: Up to approximately [e.g., 200-400 m³/h]*

-

Head Range: Up to approximately [e.g., 40-60 m]*.

-

Motor Power: [e.g., 37 kW, 45 kW, 55 kW]* – 3-Phase Induction Motor.

-

Speed: [e.g., 1750 RPM or 1450 RPM]*.

-

Material Specifications: Casing (Cast Iron/Bronze/SS), Impeller (Bronze/SS), Shaft (Stainless Steel).

Applications :

-

Main & Auxiliary Engine Seawater Cooling

-

Bilge and Ballast Pumping Systems

-

Fire Pump Systems

-

Deck Washdown

-

Cargo Hold Cleaning

-

General Transfer of Sea Water

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.