- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

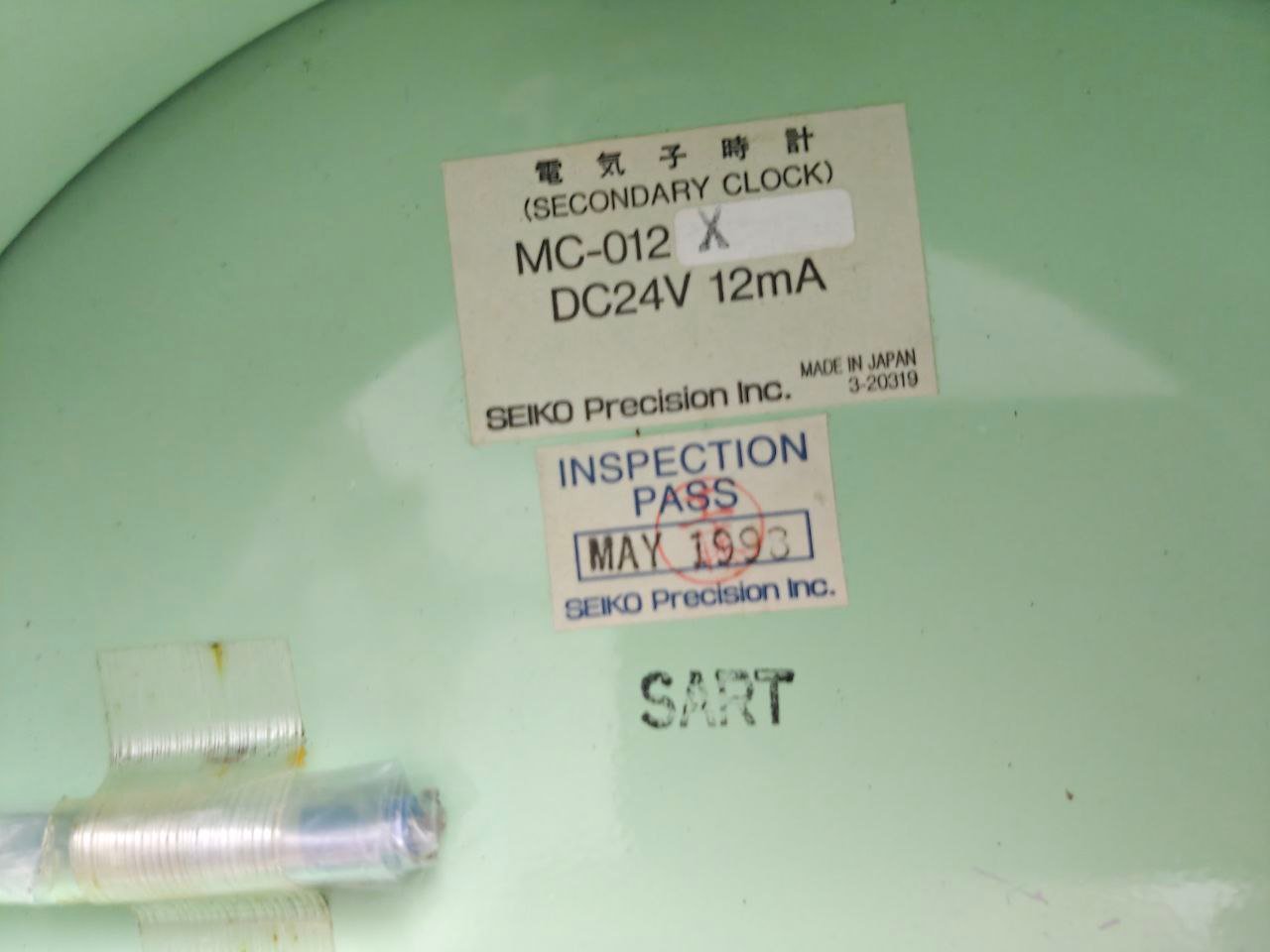

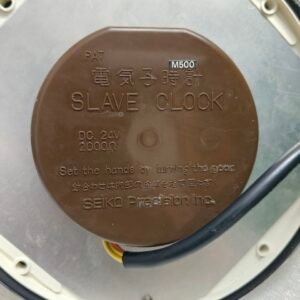

SEIKO WATCH MC-012 X M500 DC 24V 18:19

₹68,335.00

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

The SEIKO MC-012 X M500 is more than just a timer; it’s a precision instrument built for industrial endurance. Engineered by SEIKO, a name synonymous with accuracy, this device delivers unwavering performance in counting and timing operations. The integrated solid-state relay (SSR) ensures silent, spark-free, and high-speed switching, significantly outperforming traditional mechanical relays.

This model is a fundamental component for creating automated sequences, controlling processes, and managing machine cycles with exceptional accuracy.

Technical Specifications

-

Model: MC-012 X M500

-

Brand: SEIKO WATCH (Japanese Precision Engineering)

-

Power Supply Voltage: 24V DC (Please verify your supply voltage for compatibility)

-

Display: Easy-to-read digital display for setting and monitoring values.

-

Output Type: Solid-State Relay (SSR)

-

Output Configuration: 1c (SPST – Single-Pole, Single-Throw)

-

Output Load Voltage: 100-240V AC

-

Max. Load Current: 1.0A AC

-

-

Function: Preset Timer / Counter. Can be configured for various modes like ON-Delay, OFF-Delay, or Signal Counting.

-

Setting Method: Digital thumbwheel switches or pushbuttons for precise and easy configuration.

-

Mounting: Standard DIN-Rail mount (35mm), designed for easy installation in control cabinets.

-

Construction: Durable plastic housing designed to withstand typical industrial environments (dust, vibrations).

Key Advantages & Benefits

-

Legendary SEIKO Reliability: Benefit from the same precision engineering found in SEIKO timepieces, ensuring long-term accuracy and stability.

-

Solid-State Durability: The SSR output has no moving parts, meaning no contact wear, no arcing, and a vastly longer operational lifespan compared to electromechanical relays.

-

High-Speed Operation: SSR switching enables control of high-cycle processes that are too fast for mechanical relays.

-

Silent & Spark-Free Operation: Ideal for noise-sensitive environments and applications where explosive gases or dust are a concern.

-

Easy Installation & Setup: The DIN-rail mounting and clear digital interface save time during installation and commissioning.

-

Compact Design: Saves valuable space in crowded control panels.

Typical Applications

The SEIKO MC-012 X M500 is versatile and can be used in a wide range of industrial automation scenarios, including:

-

Machine Tool Control: Controlling cycle times for drilling, milling, and pressing machines.

-

Packaging Machinery: Managing fill times, sealing durations, and indexing sequences.

-

Plastic Molding Machines: Timing injection and cooling cycles.

-

Conveyor System Control: Creating delays and managing product spacing.

-

Process Automation: Controlling pump runtimes, valve sequences, and mixing operations.

-

Staging and Lighting Control: Automated sequencing for industrial displays or theatrical equipment.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.