- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

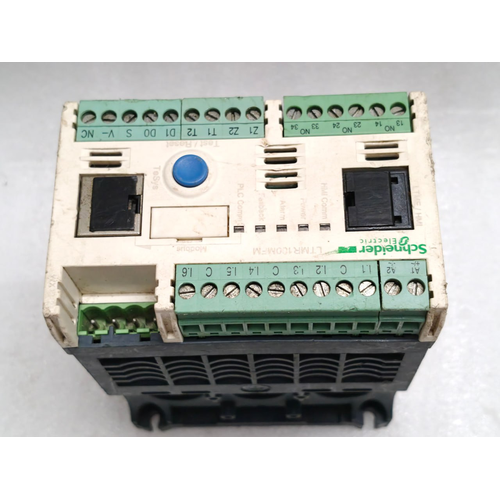

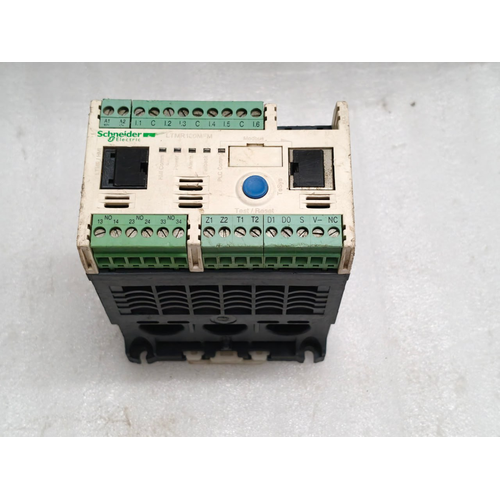

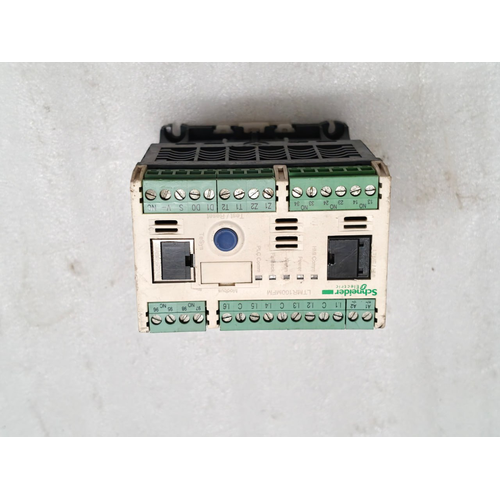

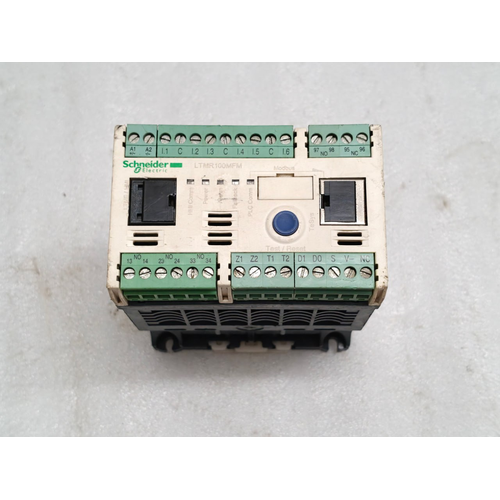

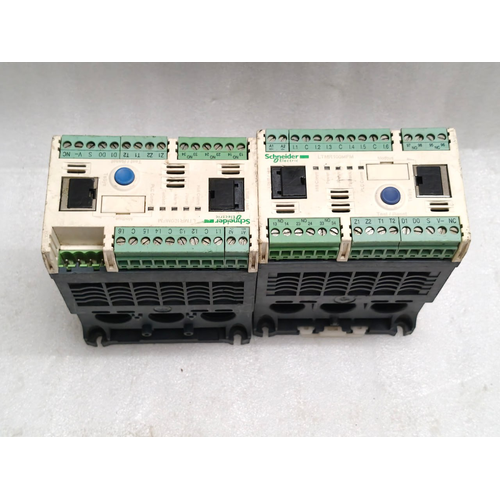

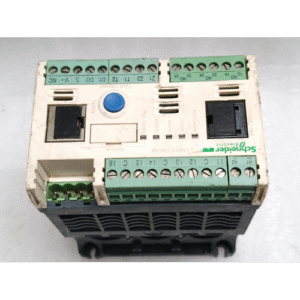

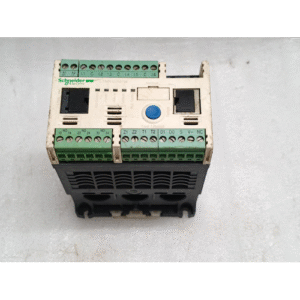

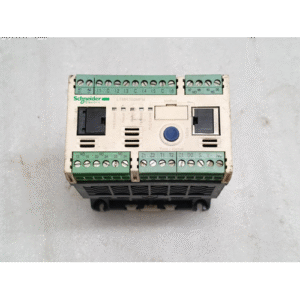

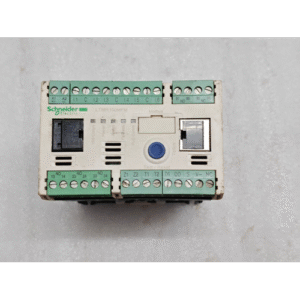

SCHNEIDER LTMR100MFM MOTOR CONTROLLER MODBUS 17:01

₹7,660.00

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

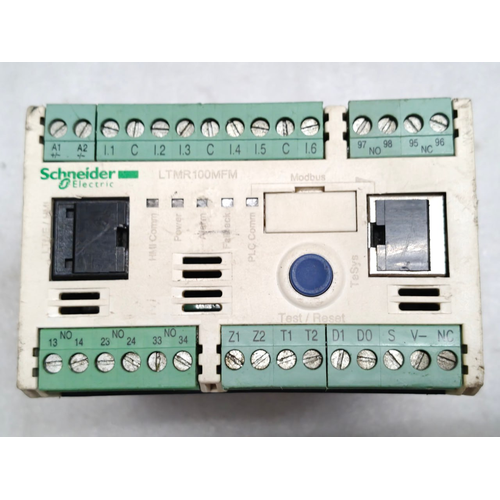

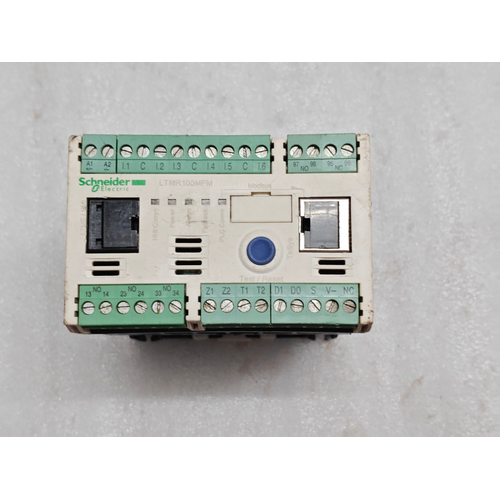

Schneider LTMR100MFM Motor Controller modbus

BRAND: SCHNEIDER

MODEL: LTMR100MFM

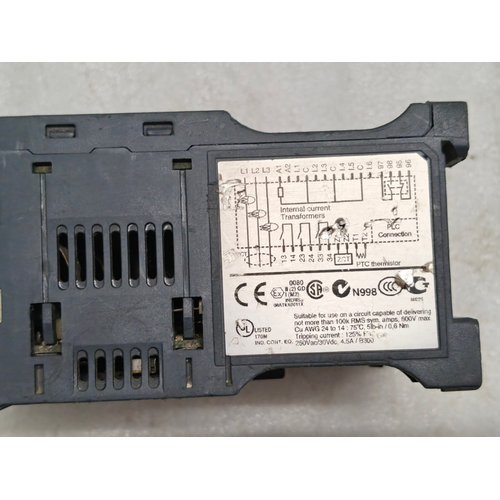

600V MAX, CU AWG 24 TO 14

75C 5LB IN / 0.6NM

TRIPPING CURRENT: 125%

250VAC/30VDC

4.4A/B300

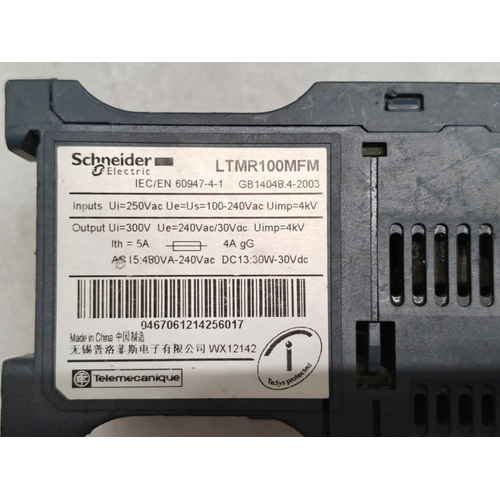

IEC/EN 60947-4-1

GB14048.4-2003

INPUT: Ui=250VAC, Ue=100-240VAC

Uimp=4KV

OUTPUT: Ui=300V, Ue=240VAC/30VAC

Uimp=4KV

Ith=5A, 4AgG

AC 15: 480VA-240VAC

DC 13: 30W-30VDC

TELEMECANIQUE

MADE IN CHINA

The Schneider Electric LTMR100MFM is a sophisticated, microprocessor-based motor management relay designed to protect, control, and monitor AC induction motors. The “Modbus” and “FM” in the model name are key: it signifies that this device is equipped with a Modbus communication interface and is certified for Factory Mutual (FM) approval for use in hazardous industrial environments.

In essence, it’s an “intelligent guardian” for your electric motor, replacing multiple discrete components (like overload relays, under-voltage relays, and phase monitoring devices) with a single, smart, and communicative unit.

Key Features and Capabilities

1. Comprehensive Motor Protection:

The primary role of the LTMR100MFM is to prevent motor damage from a wide range of electrical faults.

-

Thermal Overload Protection: Mimics the thermal characteristics of the motor, providing accurate overload protection.

-

Short-Circuit Protection: Protects against high-current faults.

-

Phase Imbalance & Loss: Detects when one phase is lost or significantly unbalanced, which can cause overheating.

-

Earth Fault (Ground Fault) Protection: Detects insulation failures to ground.

-

Undercurrent / Underpower: Protects against conditions like a pump running dry or a conveyor belt break.

-

Jam Protection: Detects mechanical jams by sensing abnormally high current after start-up.

-

Locked Rotor Protection: Prevents damage if the motor fails to start.

-

Startup Supervision & Restart Inhibit: Monitors start-up sequences and prevents immediate restart after a trip to allow the motor to cool.

2. Modbus Communication (The “SEO” Aspect):

This is a critical feature for modern industrial automation (Industry 4.0, IIoT).

-

Protocol: Communicates via the widely adopted Modbus RTU protocol over an RS-485 serial network.

-

Functionality:

-

Monitoring: Remotely read real-time data such as motor current, voltage, power, energy, thermal capacity used, trip status, and motor run time.

-

Control: Remotely start and stop the motor, reset faults, and change setpoints.

-

Configuration: Remotely configure all protection settings and parameters.

-

Alarm & Event Logging: Access a detailed history of trips, alarms, and motor events for diagnostics and maintenance.

-

3. Advanced Control and Monitoring:

-

Integrated Metering: Acts as a multi-function meter, displaying key parameters on its front panel, eliminating the need for separate instruments.

-

Programmable Logic: Features two programmable Digital Outputs (DO) and two programmable Digital Inputs (DI), allowing for custom control sequences without an external PLC in simple applications.

-

Multiple Starting Methods: Supports Direct-On-Line (DOL), Star-Delta (Wye-Delta), and other complex starting methods.

4. Robust Design and Certifications:

-

FM Approval (Explosion Proof): The “FM” suffix indicates it is certified by Factory Mutual for use in Class I, Division 2, Groups A, B, C, D hazardous locations. This makes it suitable for oil & gas, chemical, and other industries where flammable gases or vapors may be present.

-

Industrial Durability: Built to withstand the harsh conditions of industrial environments, including wide temperature ranges, humidity, and vibration.

Typical Applications

The LTMR100MFM is used anywhere a critical or large AC motor needs reliable protection and integration into a control system. Common applications include:

-

Water & Wastewater Treatment: Pumps, blowers, and compressors.

-

Oil & Gas: Pumps, fans, and drilling equipment in hazardous areas.

-

Mining & Minerals: Conveyors, crushers, and large fans.

-

Power Generation: Boiler feed pumps, ID/FD fans, and cooling water pumps.

-

HVAC: Large chillers and air handling units.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.