- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

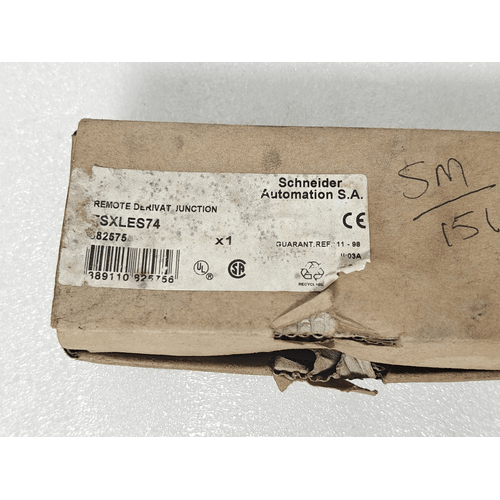

SCHNEIDER ELECTRIC TSX-LES74 / TSXLES74 REMOTE DERIVAT JUNCTION NEW FRANCE 12:53

₹31,857.00

| Product Conditioned | NEW |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

The TSX-LES74 is a remote I/O junction module used to extend the reach of a Modicon Premium PLC’s control system. It acts as a connection and communication hub between a central PLC and a bank of additional I/O modules located far away in the field, eliminating the need for long, expensive runs of individual sensor and actuator cables.

Key Identifier: “Remote Derivative JUNCTION” on the label means it is the base unit that creates a remote I/O drop on a network.

Detailed Product Description

1. Primary Function:

The TSX-LES74 serves as the head of a remote I/O station. It connects to a communication network (like FIPIO or Modbus Plus) on one side and hosts up to 7 additional “derivative” I/O modules (TSX-DExxx, TSX-DSxxx, TSX-DAx, etc.) on the other. It manages the data exchange between these I/O modules and the central processor.

2. Key Features:

-

Communication Interface: It features a FIPIO network connector. FIPIO (Factory Instrumentation Protocol I/O) was Schneider’s high-speed, deterministic fieldbus for the Premium range.

-

Integration: It can also be integrated into Modbus Plus networks using a specific network interface module (TSX-MBP100).

-

Local Expansion: The module has a backplane that supports up to 7 additional I/O modules (such as digital inputs/outputs, analog inputs/outputs, counters, etc.) directly next to it.

-

Power Supply: The entire remote drop, including the TSX-LES74 and its I/O modules, requires a separate power supply (e.g., TSX-PSPxx or TSX-PSRxx series).

-

LED Indicators: The unit features status LEDs (OK, RUN, COM, I/O) for quick diagnostics of the module’s health and communication status.

3. Technical Specifications:

-

Product Range: Modicon Premium

-

Module Type: Remote Derivative Junction

-

Number of Local Drop Slots: 7

-

Communication Network: FIPIO (Primary), Modbus Plus (via gateway)

-

Power Supply: 24 VDC (typically supplied by a separate TSX-PSRxx or TSX-PSPxx power module)

-

Compatibility: Designed to work with Modicon Premium PLCs (TSX-P57, etc.) and their associated programming software (Unity Pro).

4. Typical Application & Use Case:

Imagine a large conveyor system in a factory.

-

The main control cabinet with the Premium PLC is in the main control room.

-

A motor starter and several sensors are 200 meters away at the loading bay.

-

Instead of running dozens of wires 200 meters back to the main cabinet, you install a remote I/O station with the TSX-LES74 at the loading bay.

-

You plug a digital output module (e.g., TSX-DSY16T2) into the LES74 to control the motor starter, and a digital input module (e.g., TSX-DEY16D2) to read the sensors.

-

A single, robust FIPIO network cable is then run from the main PLC to the TSX-LES74, carrying all the control and data signals for that entire area. This saves significant cost, wiring time, and complexity.

5. Status: Legacy / Discontinued

Important Note: The Modicon Premium platform is considered a legacy product line. While still widely used in many existing industrial installations, it has been largely superseded by the newer Modicon M580 ePAC (Ethernet Programmable Automation Controller) platform.

-

For New Projects: Schneider Electric strongly recommends using the Modicon M580 and its associated Ethernet-based I/O (e.g., X80 drops) for new system designs.

-

For Existing Systems: The TSX-LES74 and its modules are typically only sourced on the aftermarket or refurbished market for maintenance, repair, or minor expansion of existing Premium systems.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.