- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

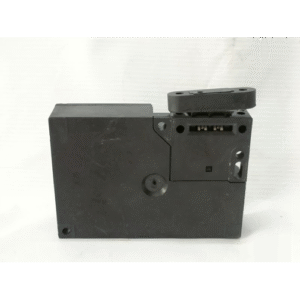

Schmersal AZM 161SK-12/12RKA-024 Safety Interlock Switch

₹12,711.00

| Product Conditioned | NEW |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

Specifications:

Type: Switch Lock

Model: AZM 161SK-12/12RKA-024 AZM 161SK-12/12RK-024

The Schmersal AZM 161SK-1212RKA-024 is a robust, solenoid-locked safety interlock switch designed to safeguard personnel by preventing access to hazardous machinery during operation. It is a key component in safety systems for guards, doors, and movable panels that require a high level of safety integrity.

This specific model is part of Schmersal’s AZ 16 series, known for its high safety rating and reliable performance.

High-Level Summary

This is a positively-guided, lockable safety switch with a separate solenoid release. It ensures that a guard door remains locked and the machine is in a safe state until a hazardous process is complete. Only then can the door be unlocked and opened. It features two normally closed (NC) safety contacts and one normally open (NO) auxiliary contact, all with positive-guided operation.

Breakdown of the Product Code (Ordering Code)

Schmersal’s product codes are highly descriptive. Here’s what each part means:

-

AZM 161: The base model series (AZM 16) with a specific actuator type (1).

-

S: Solenoid Locking. This is the key feature, indicating the switch has an electromagnetic lock.

-

K: Actuator Type. This signifies a “cam” or “latch” style actuator, typically a separate component that mounts on the guard door.

-

-12: Contact Configuration 1. 1 NC (Safety) + 1 NO (Auxiliary) contact.

-

-12: Contact Configuration 2. Another 1 NC (Safety) + 1 NO (Auxiliary) contact. This gives a total of 2 NC and 1 NO contacts.

-

R: Release by External Control. The solenoid lock is released by applying/removing the supply voltage externally (e.g., by a safety relay).

-

K: Mounting Flange. This refers to the specific shape and hole pattern of the switch’s mounting bracket.

-

A: Actuator Coding. “A” is a standard coding level. Higher letters (B, C, etc.) indicate more unique codings to prevent circumvention.

-

-024: Voltage Code for Solenoid. This specific code indicates the solenoid coil is rated for 24V DC.

Key Features

-

Solenoid Locking: The main safety feature. The guard door is physically locked shut. The lock can only be released via a signal from the safety control system (e.g., a safety relay) once it is safe to do so.

-

Positive-Guided Mechanism (EN 60947-5-1): The safety contacts (NC) are mechanically linked to the auxiliary contact (NO) in such a way that they can never be closed simultaneously. This prevents a “stuck” NO contact from falsely indicating the door is locked when the safety contacts are open. This is a fundamental requirement for safety circuits.

-

High Safety Rating: Complies with international standards and can achieve:

-

Safety Category 4 / PL e according to EN ISO 13849-1.

-

SIL 3 according to IEC 61508 / IEC 62061.

-

-

2 NC + 1 NO Contacts: The two NC contacts are used in the redundant safety circuit to monitor the door’s position. The NO contact is typically used to signal the “locked” status to the controller or for a muting function.

-

Separate Actuator: The switch uses a separate, cam-style actuator that mounts on the movable guard. This allows for precise adjustment and ensures reliable operation.

Technical Specifications (General for AZM 161 Series)

-

Safety Contacts (2 NC):

-

Rated Operating Current: 6 A

-

Rated Insulation Voltage: 500 V

-

Utilization Category: AC-15: 230V / 3A; DC-13: 24V / 2A

-

-

Auxiliary Contact (1 NO):

-

Rated Operating Current: 2 A

-

-

Solenoid Lock:

-

Voltage: 24V DC (as specified by -024)

-

Duty Cycle: Typically 100% (can be powered continuously)

-

Power Consumption: Approximately 7.5 W (check datasheet for exact value)

-

-

Mechanical Life: > 2,000,000 operations

-

Electrical Life: > 200,000 operations (at rated load)

-

Enclosure Rating: Typically IP67 (Dust-tight and protected against immersion)

-

Connection: Typically via a M12 x 1, 5-pin connector (separate terminals for the solenoid may exist).

Typical Applications

This switch is used in applications where it is critical that a guard remains closed and locked until the machine cycle is complete and all hazards have ceased.

-

Robotic Cells

-

Press Brakes

-

Injection Molding Machines

-

Packaging Machinery

-

Automated Assembly Lines

-

Any area with dangerous moving parts that take time to come to a complete stop.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.