- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

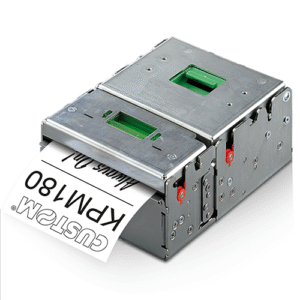

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

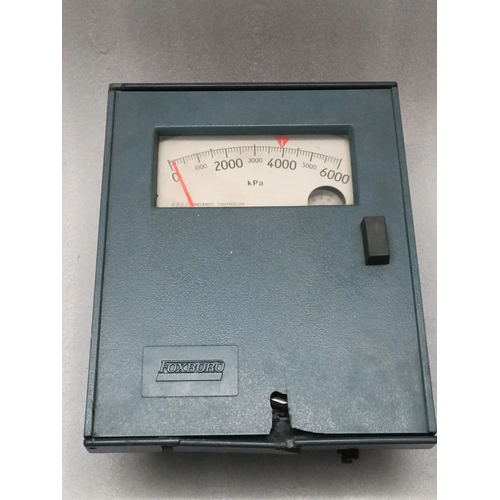

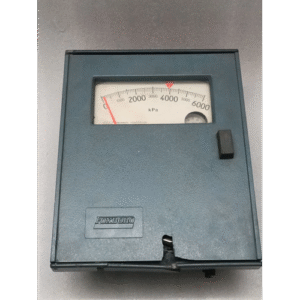

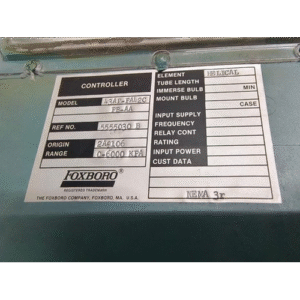

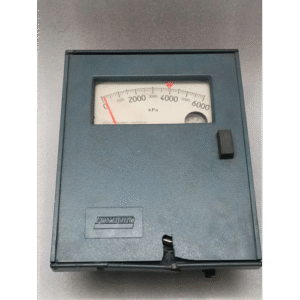

FOXBORO 43AP-PA42C-PB-AA PNEUMATIC CONTROLLER 0-6000 KPA HELICAL

₹229,082.00 Original price was: ₹229,082.00.₹228,944.00Current price is: ₹228,944.00.

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

- 43AP PA42C PB AA

- DISCONTINUED BY MANUFACTURER

- PNEUMATIC CONTROLLER

- PROPORTIONAL + RESET

- 0-6000 KPA RANGE

- BUMPLESS AUTO/MANUAL SWITCH

- SS GAUGE PRESSURE ELEMENT CALIBRATED

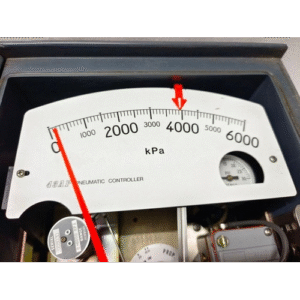

The Foxboro 43AP is a self-contained, pneumatic motion-balance controller designed for direct installation in the field, close to the process measurement point. The specific model 43AP-PA42C-PB-AA is configured for very high pressure applications, using a helical Bourdon tube as its sensing element. It provides a proportional (P) and automatic reset (integral, I) control output to a pneumatic final control element, such as a control valve or damper actuator.

Detailed Model Number Breakdown (Nomenclature)

Foxboro model numbers are highly descriptive. Here’s what each segment means:

-

43AP: The base model number for this series of pneumatic controllers.

-

P: Process Connection.

Pspecifies a 0.25″ NPT (F) female connection. -

A: Case Option.

Aspecifies a general-purpose, weatherproof (but not explosion-proof) case. -

42: Control Action.

42specifies Direct-Acting, Proportional plus Automatic Reset (PI) control.-

Direct-Acting: The output pressure increases as the measured process variable increases.

-

Proportional (P): The output change is proportional to the deviation from the setpoint.

-

Automatic Reset (I): Automatically eliminates droop (offset) by continually adjusting the output over time as long as an error exists.

-

-

C: Measured Variable / Sensor Type.

Cspecifies a Helical Bourdon Tube. This is a coiled, hollow tube that untwists as internal pressure increases. It is specifically chosen for this model’s 0-6000 KPA range, as it is ideal for very high pressures. -

P: Setpoint Adjustment.

Pspecifies a Local, Rack & Pinion setpoint adjustment knob located on the front of the controller. -

B: Control Pressure Range.

Bspecifies a 3-15 PSI (0.2-1.0 bar) standard pneumatic output signal. -

AA: Accessories / Specials.

AAtypically indicates no special accessories or a standard factory configuration.

Key Features & Operational Description

-

Helical Bourdon Tube Sensor (PA42C):

-

The core sensing element is a helical (spirally wound) tube.

-

Process pressure (0-6000 KPA) entering the tube causes it to partially uncoil.

-

This rotary motion is mechanically linked to the controller’s balancing mechanism.

-

Advantage: Excellent for high pressure, provides good sensitivity and a long, durable stroke.

-

-

Pneumatic PI Control (42):

-

This is a motion-balance system. The mechanism balances the motion from the measurement element against the motion from the setpoint and feedback bellows.

-

It generates a standard 3-15 PSI output signal based on the difference (error) between the process variable and the local setpoint.

-

The Proportional Band (gain) and Reset Rate (integral time) are adjustable via internal screws or knobs, allowing the control response to be tuned for the specific process.

-

-

Field-Mounted Design:

-

Built for harsh environments. The case is weatherproof, protecting the internal mechanism from dust and rain.

-

Mounts directly on the process line or a nearby stanchion, eliminating the need for long impulse lines and reducing measurement lag.

-

-

Local Indication & Setpoint:

-

Features a local pointer and scale to show the current process pressure.

-

The setpoint is adjusted locally via a knob, with its own pointer and scale.

-

Typical Applications

This controller is designed for high-pressure industrial processes, such as:

-

Boiler Steam Header Pressure Control

-

High-Pressure Natural Gas Line Regulation

-

Chemical Process Reactors

-

Hydrostatic Testing Pressures

-

Water & Wastewater High-Pressure Pump Discharge

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.