- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

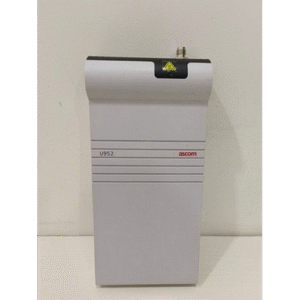

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

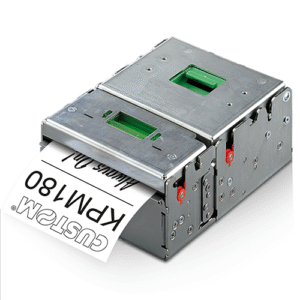

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

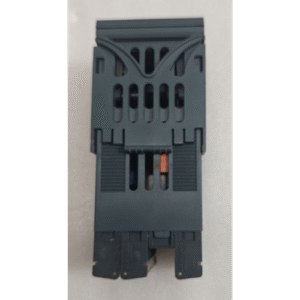

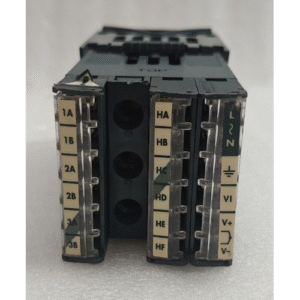

EUROTHERM 2216E TEMPERATURE CONTROLLER 11:45

₹13,524.00

| Product Conditioned | USED |

|---|

In simple terms, this is the “precision brain for controlling heat” in an industrial machine.

It’s a high-quality, heavy-duty digital unit that you’d find on the control panel of an oven, dryer, or plastic machine. You tell it the temperature you want (the setpoint), and it automatically manages the power to the heater (or cooler) to hit and hold that exact temperature, compensating for changes in the environment. It’s a workhorse of industry. Buying it used means you’re getting a proven reliable unit, but you’ll need to know how to wire it and program it for your specific job.

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

The Eurotherm 2216e is a compact, versatile, and highly reliable single-loop temperature controller designed for industrial process control. It is a digital panel meter that automates the task of maintaining a precise temperature by reading a sensor (like a thermocouple) and controlling an output device (like a heater or cooler).

Key Features & Specifications

-

Manufacturer: Eurotherm (A renowned and highly respected British manufacturer of precision industrial control systems, now part of Schneider Electric). The brand is synonymous with quality and reliability in harsh environments.

-

Model: 2216e – This indicates it’s part of the 2216 series, with the “e” often denoting an enhanced or specific variant.

-

Type: PID Temperature Controller. PID (Proportional-Integral-Derivative) is a sophisticated control algorithm that not only turns the output on/off but adjusts the power level precisely to maintain a stable temperature without overshoot or oscillation.

-

Input: Accepts a wide range of industry-standard temperature sensors:

-

Thermocouples (Types J, K, T, R, S, B, N, E)

-

RTDs (Pt100)

-

Voltage and Current signals (0-10V, 0/4-20mA) for use with other process sensors.

-

-

Outputs: Typically offers multiple output options (configurable):

-

Relay Output: (e.g., 5A SPDT) for directly switching heaters, contactors, or solenoid valves.

-

SSR Drive: (e.g., 12V DC) for controlling solid-state relays (SSRs) for fast, long-life switching.

-

Analog Output: (e.g., 0/4-20mA or 0-10V) for controlling proportioning valves or variable speed drives.

-

-

Display: A bright, easy-to-read LED or Vacuum Fluorescent Display (VFD) that shows the Process Value (PV) (actual temperature) and Set Value (SV) (desired temperature).

-

Control Algorithm: Advanced PID with features like Autotune (the controller automatically calculates the optimal P, I, and D values for the system it’s connected to), manual tuning, and alarm functions.

-

Enclosure: Designed for panel mounting in a standard DIN cutout (e.g., 1/16 DIN or 1/8 DIN), making it a staple in industrial control panels worldwide.

What is it used for? (Purpose)

This controller is the “brain” for any application that requires precise and stable temperature regulation. Common applications include:

-

Industrial Ovens & Furnaces (for heat treating, curing, drying)

-

Plastic Processing Machinery (extruders, injection molders)

-

Packaging Equipment

-

Food and Beverage Processing

-

Environmental Chambers and Test Equipment

-

HVAC systems for specialized industrial heating

Who is this for? (Ideal User)

This is a professional industrial component for:

-

Industrial Electricians and Control Systems Technicians.

-

Maintenance Engineers in manufacturing plants.

-

Process Engineers.

-

Machine Builders and Panel Builders.

-

Advanced Hobbyists or Lab Technicians working with high-temperature processes (e.g., kilns, foundries).

Important Considerations for a “USED” Unit

-

Configuration: This is a highly configurable device. Its behavior depends entirely on how it has been programmed (e.g., input type, output type, PID values, alarm settings). A used unit will likely need to be completely re-configured for your specific application.

-

Documentation: Access to the user manual or datasheet is essential to understand how to wire it and program it correctly.

-

Physical Condition: Check for signs of overheating on the terminals or display failure.

-

Calibration: While generally very stable, the accuracy of the input reading may need to be verified or calibrated against a known standard if precision is critical.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.