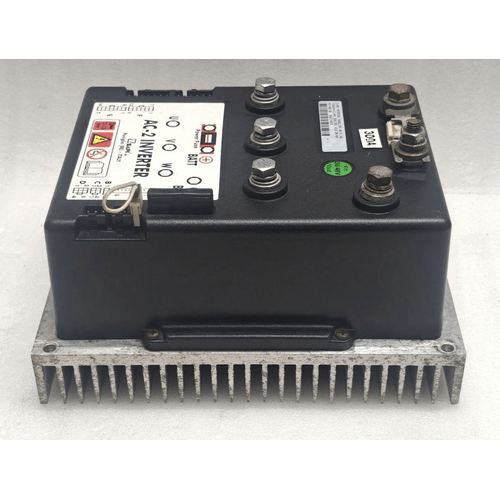

The CLARK FZ5024A (ZAPI PUMP AC2) is a programmable, high-performance DC motor controller designed exclusively to operate the hydraulic pump motor on an electric forklift or other material handling equipment.

This particular unit, with its #5 amperage code, is an ultra-high-rated pump controller. Its purpose is to power the hydraulic pump that creates extreme pressure for lifting and lowering very heavy loads at high speeds, tilting the mast under full load, and operating demanding attachments. It is engineered for the most severe applications where maximum hydraulic power and torque are required.

Key Specifications from the Label

-

OEM Brand: CLARK

-

Clark Controller Model: FZ5024A

-

Clark Part Number: 8051761

-

Actual Manufacturer/Technology: ZAPI (The “AC2” is a ZAPI series identifier for pump controls).

-

Function: PUMP INVERTER CONTROL (Dedicated hydraulic pump controller).

-

Operating Voltage: 36V or 48V DC (Compatible with both battery systems; must be configured for the correct voltage in software).

-

Current Rating: The “#5” is a Clark-specific amperage code. For pump controllers, #5 indicates an ultra-high amperage rating, typically in the range of 275-300 Amps. This is designed for the most extreme hydraulic applications.

Key Features and Functions

-

Ultra-High Power Pump Control: Designed for severe-duty hydraulic systems that require extreme power, such as lifting very heavy loads to full height quickly or operating multiple high-pressure attachments simultaneously.

-

Smooth & Precise Control at Maximum Power: Manages extremely high current flow to ensure smooth operation of the hydraulic pump, reducing mechanical shock and allowing for precise load handling even under maximum load.

-

Advanced Programmability: Requires a ZAPI programmer to configure operational parameters, including:

-

Maximum pump speed (lift and lower)

-

Acceleration and deceleration rates

-

Current (torque) limit (set by the #5 / ~275-300A hardware)

-

Diagnostic and protection settings

-

-

Comprehensive Diagnostics: Features advanced self-diagnostics and stores error codes for faults such as:

-

Pump motor over-current

-

Controller over-temperature

-

Short circuit protection

-

Low battery voltage detection

-

-

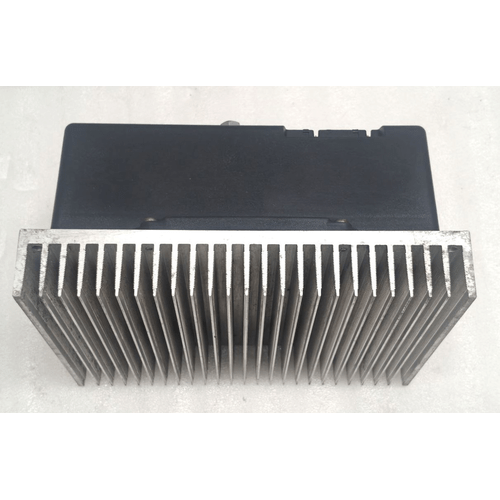

Heavy-Duty Protection Circuits: Includes robust built-in protection for the pump motor and controller, including enhanced thermal overload and under-voltage shutdown, critical for handling the extreme electrical demands.

Common Applications

This ultra-high-capacity pump controller is used in the largest 36V/48V Clark electric material handling equipment where superior hydraulic performance is critical. Applications include:

-

High-Capacity Clark Electric Forklifts (e.g., 10,000+ lb capacity)

-

Clark Electric Forklifts with multiple high-pressure attachments

-

Container Handlers and other specialized high-force equipment

-

Any application requiring the absolute maximum hydraulic power available from a 36/48V system

Important Notes for Replacement/Repair

-

Specialized Ultra-High-Power Function: This is exclusively a maximum-capacity pump controller. It is not interchangeable with lower-rated pump controllers (#1, #2, #3, #4) or any traction controllers.

-

ZAPI Technology Mandatory: The “AC2” is proprietary to ZAPI. It requires ZAPI-specific tools and software for programming and diagnostics.

-

Critical Amperage Match: The amperage code (#5) is absolutely essential and must be matched exactly. Using a lower-rated controller will result in failure to perform, while using an incorrect controller could cause catastrophic damage to the hydraulic system.

-

Programming Required: A new or replacement unit will be blank and must be programmed with the correct parameters for the specific vehicle application.

-

Core Value: This ultra-high-power unit has a significant core value and should be returned for a substantial credit when exchanging for a rebuilt unit.