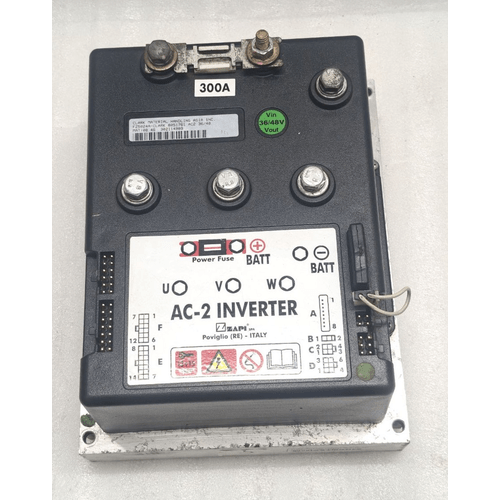

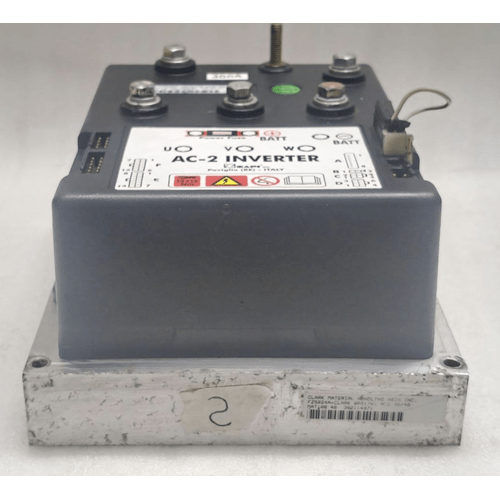

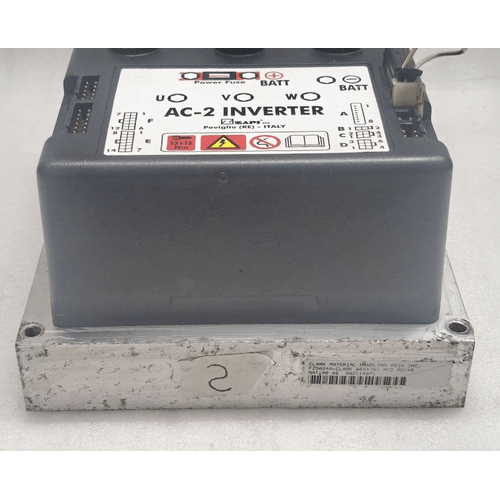

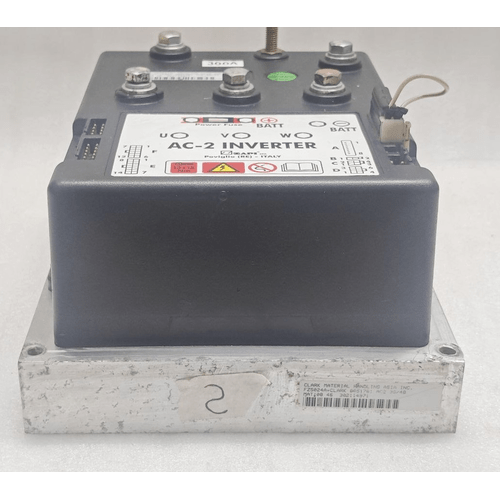

The CLARK FZ5024A (ZAPI PUMP AC2) is a programmable, single-function DC motor controller designed exclusively to operate the hydraulic pump motor on an electric forklift or other material handling equipment.

Its sole purpose is to power the pump that creates hydraulic pressure for lifting and lowering loads, tilting the mast, and operating any attachments. It receives signals from the operator’s hydraulic controls (levers/buttons) and delivers the precise amount of power to the pump motor to perform the requested function at the desired speed and power.

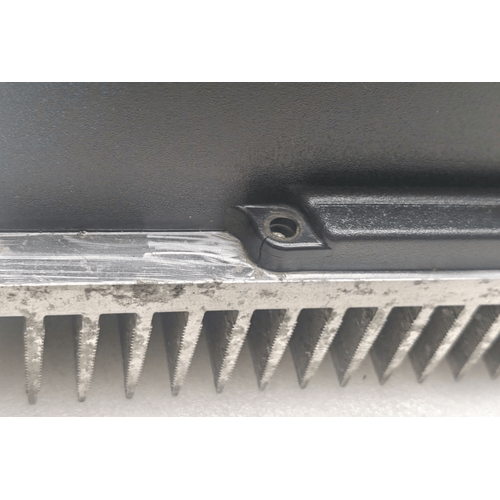

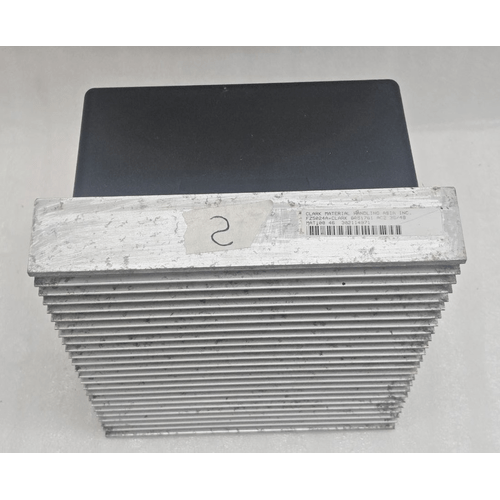

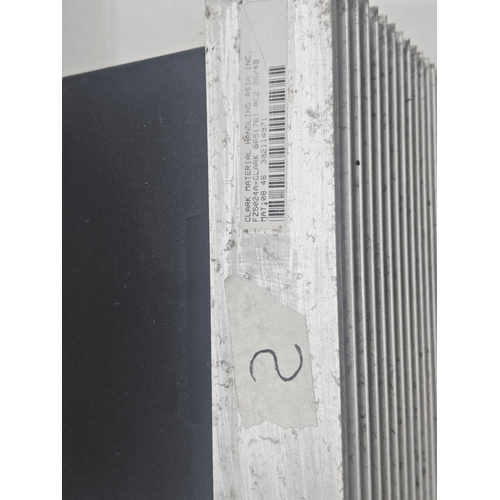

Key Specifications from the Label

-

OEM Brand: CLARK

-

Clark Controller Model: FZ5024A

-

Clark Part Number: 8051761

-

Actual Manufacturer/Technology: ZAPI (The “AC2” is a ZAPI series identifier for pump controls).

-

Function: PUMP INVERTER CONTROL (Dedicated hydraulic pump controller).

-

Operating Voltage: 36V or 48V DC (Compatible with both battery systems; must be configured for the correct voltage in software).

-

Current Rating: The “#2” is a Clark-specific amperage code. For pump controllers, #2 indicates a higher amperage rating than a #1, often in the range of 120-150 Amps. This higher rating provides more power and torque for demanding hydraulic applications, such as lifting heavier loads or faster cycle times.

Key Features and Functions

-

Dedicated Pump Control: Designed specifically for the demanding start-stop and variable speed needs of a hydraulic pump motor. It is not designed to control traction.

-

Smooth & Precise Control: Provides smooth acceleration of the hydraulic pump, reducing mechanical shock to the system and allowing for precise, controlled load handling (e.g., fractional lifting/lowering, “inching”).

-

Programmability: Requires a specialized programmer (typically a ZAPI unit) to configure parameters such as:

-

Maximum pump speed (for lift and lower)

-

Acceleration and deceleration (ramp) rates

-

Current (torque) limit (set by the #2 / ~120-150A hardware) to protect the pump motor and hydraulic system from overload

-

Diagnostic settings

-

-

Integrated Diagnostics: Features self-diagnostics and can store error codes for faults like:

-

Pump motor over-current

-

Controller over-temperature

-

Short circuit

-

Low battery voltage

-

-

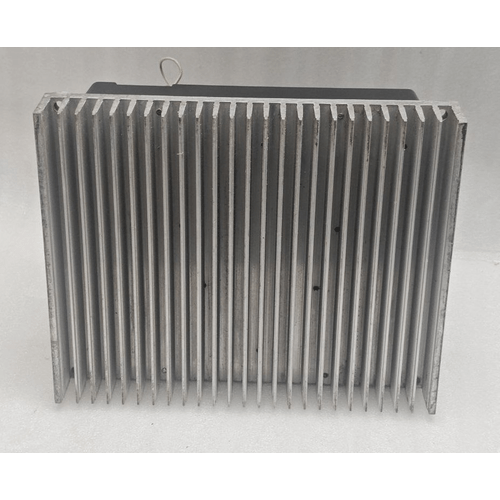

Protection Circuits: Built-in protection for the pump motor and itself, including thermal overload and under-voltage shutdown.

Common Applications

This controller is found on 36V/48V Clark electric material handling equipment where a higher-capacity hydraulic pump is required. It is used in systems where the pump is controlled separately from the drive. Examples include:

-

Larger Clark Electric Forklifts (with higher lifting capacities)

-

Clark Electric Reach Trucks

-

Clark Electric Order Pickers

-

Any application where the standard #1 (90-110A) pump controller is insufficient.

Important Notes for Replacement/Repair

-

Function is Critical: This is only a pump controller. It cannot be used to replace a traction controller (like a DUALAC2) or a combined controller (like a COMBIAC2).

-

ZAPI Technology: The “AC2” nomenclature is proprietary to ZAPI. It must be treated as a ZAPI component for programming and diagnostic purposes.

-

Amperage Match is Essential: The amperage code (#2) must be matched when replacing. Installing a controller with a lower rating (#1) would result in weak hydraulic performance. Using one with a higher, incompatible rating could lead to damage of the pump motor or hydraulic system.

-

Programming is Required: A new or replacement unit will be blank and must be programmed with the correct parameters for the specific vehicle.

-

Core Value: This unit has a core value and should be returned to the supplier for a significant credit when exchanging for a rebuilt unit.