- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

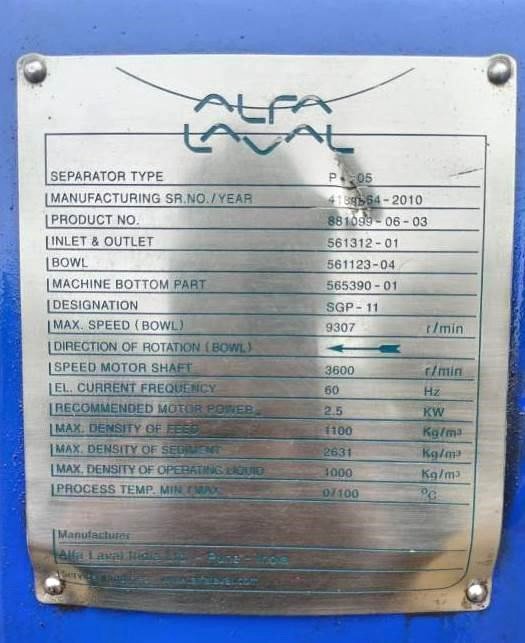

ALFA LAVAL INDUSTRIAL CENTRIFUGAL SEPARATOR MODULE TYPE. P 605 SGP-11

$0.00

| Product Conditioned | NEW |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

Alfa Laval P 605 SGP-11 Centrifugal Separator Module

1. Primary Function & Applications

The P 605 SGP-11 module is engineered for continuous, high-volume separation of two liquids with simultaneous removal of solids. Its typical applications are:

-

Marine & Offshore: Treatment of heavy fuel oil (HFO), marine diesel oil (MDO), and lubricating oils (LO) on board ships and offshore platforms.

-

Power Generation: Purification of fuel oils for auxiliary and main engines in power plants.

-

Industrial Processing: Separation and clarification of various industrial oils, process fluids, and biofuels.

2. Core Component: The Separator (Bowl)

-

Type: P 605 indicates a large-diameter disc stack separator, specifically a purifier. This means it is designed to separate two immiscible liquids of different densities (e.g., oil and water) while discharging accumulated solids.

-

Operation: It operates as a self-cleaning (hermetic) separator. The bowl is closed and fed under pressure, making it ideal for handling volatile liquids and preventing air entrainment. It features an automated desludging mechanism to periodically eject collected solids and sludge without stopping the process.

3. Key Characteristics of the “SGP-11” Module Designation

-

SGP: This typically stands for “Separator, General Purpose” or denotes a specific modular frame and system configuration. It signifies a standardized, pre-assembled skid.

-

-11: This suffix often refers to a specific variant or configuration package, which could include:

-

A particular arrangement of heaters, pumps, and control systems.

-

The inclusion of specific automation features (e.g., Alcap/Sensoline water-in-oil monitoring systems).

-

A design tailored for a specific viscosity range or duty.

-

4. Module Components & System Integration

The “Module” aspect means it is not just a separator, but a complete, pre-piped, wired, and tested system on a common baseplate (skid). Key integrated components include:

-

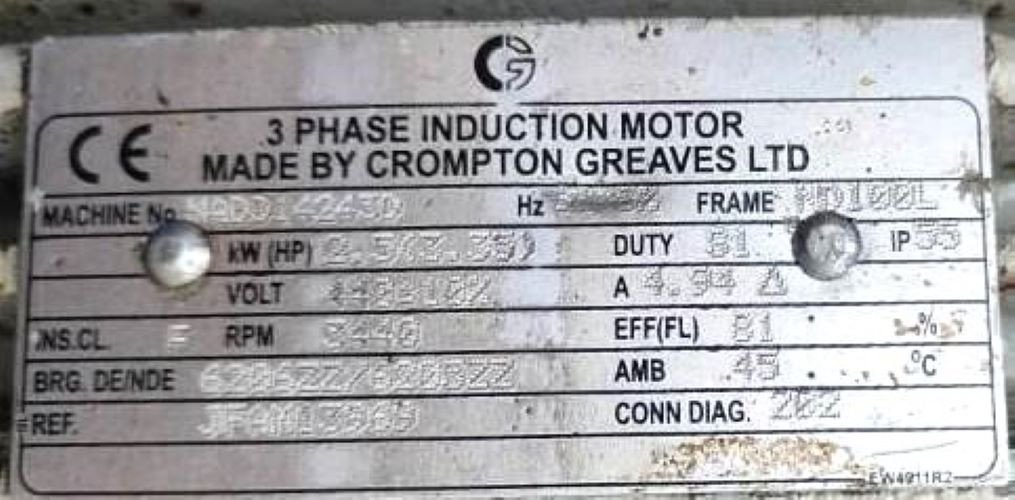

Separator Unit: The Alfa Laval P 605 purifier bowl assembly with motor.

-

Feed & Transfer Pumps: Electrically driven pumps for supplying oil to the module and transferring cleaned oil onward.

-

Heating System: An electrical or steam-heated pre-heater to reduce the viscosity of the feed oil for optimal separation efficiency.

-

Control Panel / Automation: A comprehensive control system for automatic start/stop, temperature regulation, desludging sequencing, and alarm monitoring. It often features a programmable logic controller (PLC).

-

Piping & Valves: All necessary interconnecting piping, valves (manual and automatic), and instrumentation (pressure gauges, thermometers).

-

Sludge Tank: An integrated tank for collecting discharged solids.

5. Key Technical Features & Benefits

-

High Capacity: The P 605 bowl is designed for large flow rates, suitable for main engine fuel supply on medium to large vessels or industrial plants.

-

Process Reliability: Hermetic design and automated controls ensure stable, efficient separation with minimal operator intervention.

-

Reduced Installation Time & Cost: As a pre-assembled module, it requires only basic utility connections (power, inlet/outlet piping), drastically reducing commissioning time and risk of installation errors.

-

Built-in Safety: Includes safety interlocks, alarms for high/low pressure, high temperature, and other critical parameters.

-

Compliance: Designed to meet relevant marine (IMO) and industrial standards.

6. Typical Process Flow

-

Supply: Raw oil is drawn from a storage/settling tank.

-

Heating: The oil passes through the pre-heater to reach optimal separation temperature (~85-98°C for HFO).

-

Separation: The heated oil is fed under pressure into the rotating P 605 bowl. Centrifugal force separates water and solid impurities from the clean oil.

-

Discharge: Clean oil is discharged continuously under pressure to a service tank. Separated water is discharged continuously. Solids (sludge) are ejected at programmed intervals into the integrated sludge tank.

-

Control: The entire process is monitored and controlled by the automated system.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.