- AUTOMATION EQUIPMENT

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- UNCATEGORIZED

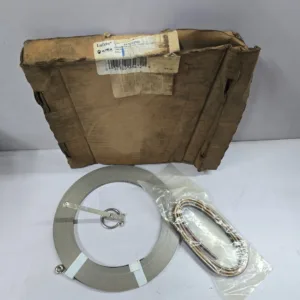

Electronics Inc AC-24 Amperage Controller CPN 999330 SO 39256 S/N 3504

₹39,840.00

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

Electronics Inc AC-24 Amperage Controller CPN 999330 SO 39256 S/N 3504

- Monitors motor current

- Four-digit display

- 10 LED bar graph

- High-low alarm contacts

- Accepts remote command setpoint

- Provides analog recorder output

- Easy panel mounting (1/2 DIN)

- Provides automatic operation (closed-loop system) for the LP-24, VLP-24 and WM 3000-24 MagnaValve

- 24 Vdc

- CE compliant

The AC-24 Controller provides automatic operation ( a closed-loop system) for the MagnaValve. The feedback from the controller allows the MagnaValve to regulate steel shot in shot peening and blast cleaning applications where accurate and repeatable flow rates are desired. The controller may operate as a stand-alone control or work with a customer’s programmable controller via standard analog 0-10 Vdc interface.

Electronics Inc AC-24 Amperage Controller

Product Identification:

-

Product Name: AC-24 Amperage Controller

-

Manufacturer: Electronics Inc.

-

Catalog Part Number (CPN): 999330

-

Sales Order (SO): 39256

-

Serial Number (SN): 3504

Executive Summary

The Electronics Inc. AC-24 is a precision industrial amperage controller designed for reliable regulation and monitoring of electrical current in a wide range of applications. Identified by CPN 999330 and serial number 3504, this unit is part of a specific production batch (SO 39256), ensuring traceability and quality control. It is engineered to provide stable and accurate control over 24V AC systems, making it a critical component for motor management, heating control, lighting systems, and complex machinery.

Detailed Product Description

The AC-24 Amperage Controller is a solid-state or relay-based control device that acts as the “brain” for managing electrical current flow. It continuously monitors the amperage in a circuit and makes real-time adjustments to maintain a pre-set level or to trigger specific actions when a threshold is reached.

1. Key Functions:

-

Current Regulation: Maintains a consistent amperage level to protect sensitive equipment from under-current or over-current conditions.

-

Over-Current Protection: Safely interrupts or limits the circuit if the current exceeds a predefined safe operating limit, preventing damage to motors, heaters, and other components.

-

Load Management: Enables the sequential starting or proportional control of multiple devices to manage inrush currents and prevent circuit overloads.

-

Process Control: Integrates into automated systems to control processes where amperage is a key variable, such as in electroplating, welding, or power supply regulation.

2. Typical Applications:

-

Industrial Motor Control: For controlling the startup, running, and overload protection of AC motors.

-

Heating Element Control: Managing the power to resistive heating loads in ovens, furnaces, and industrial heaters.

-

Lighting Systems: Controlling current in architectural, theatrical, or industrial lighting arrays.

-

Power Distribution Panels: As a modular component in custom electrical panels for machinery and facility management.

-

Pump and Fan Control: Regulating the speed or operational state of pumps and fans based on system demand.

3. Technical Specifications (Generic):

-

Input Voltage: 24V AC (Standard for the model; specific variants may exist).

-

Control Output: Relay contact or Solid-State (SSR) driver.

-

Current Sensing Range: [*Typical Range, e.g., 0.1 – 20A*] – Specific to the sensor and model variant.

-

Setpoint Adjustment: Via onboard potentiometers, DIP switches, or through a digital communication interface.

-

Status Indication: LED indicators for Power, Load Active, and Fault conditions.

-

Mounting: Designed for standard DIN rail installation.

-

Communication (Optional): May support protocols like Modbus, Profibus, or DeviceNet for integration into PLC-based systems (dependent on exact variant).

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.