- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- SENSORS

- UNCATEGORIZED

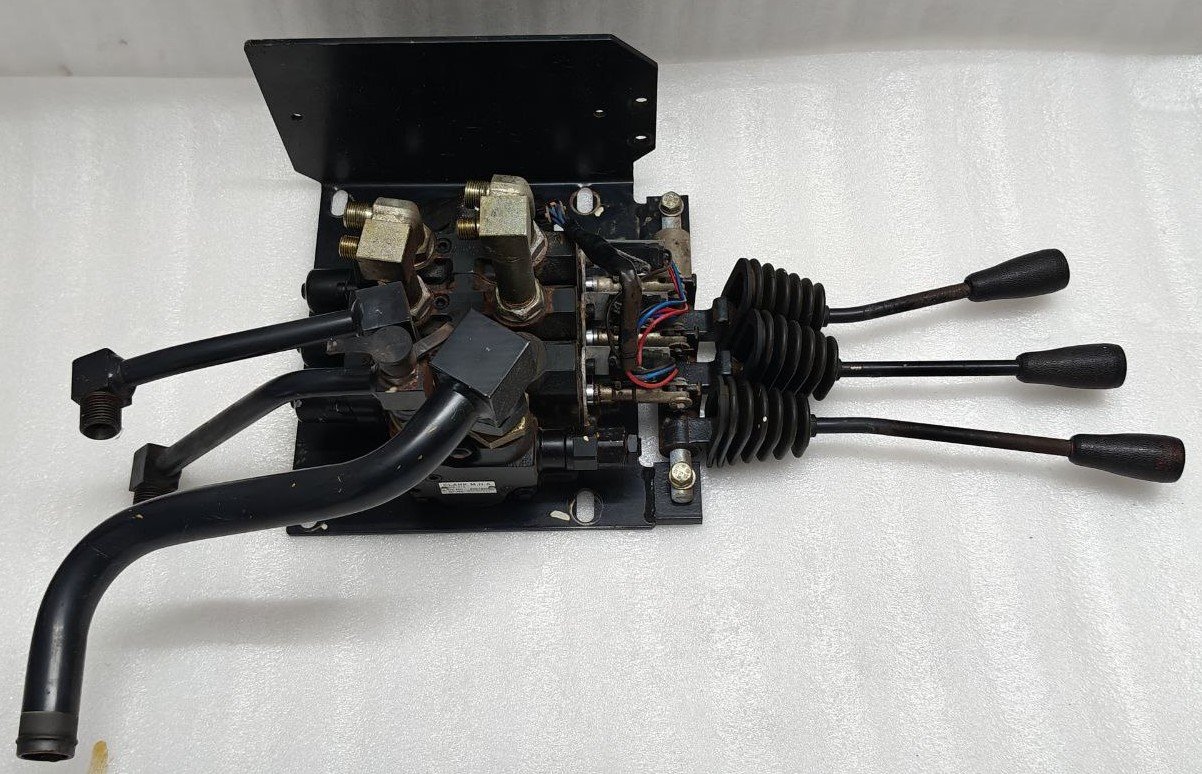

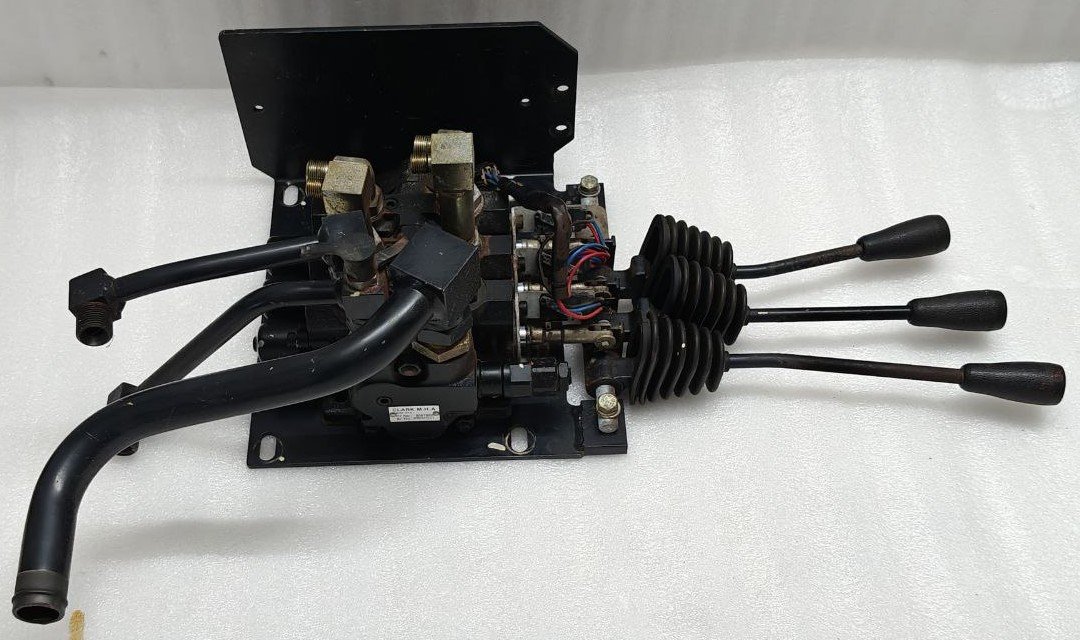

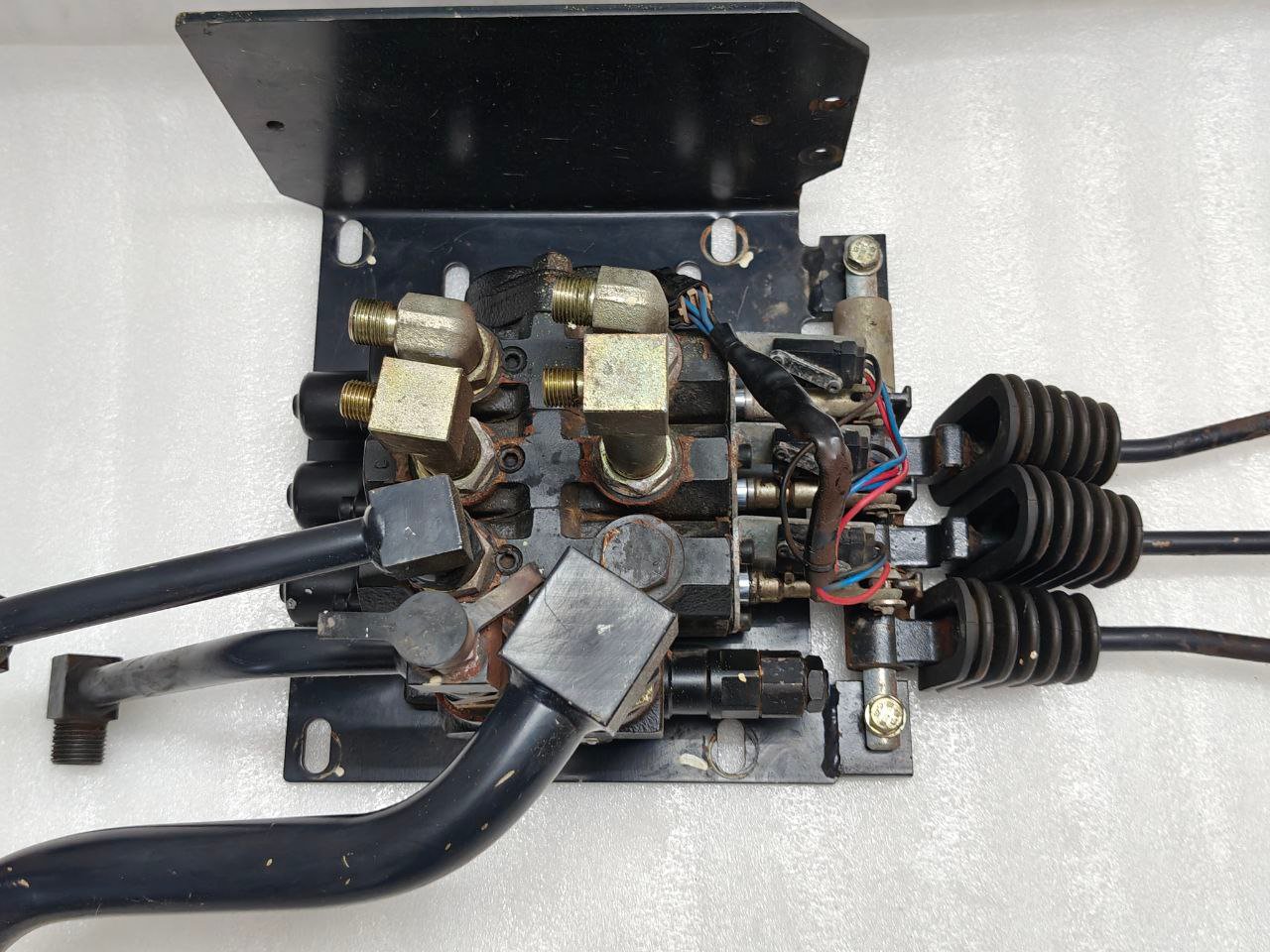

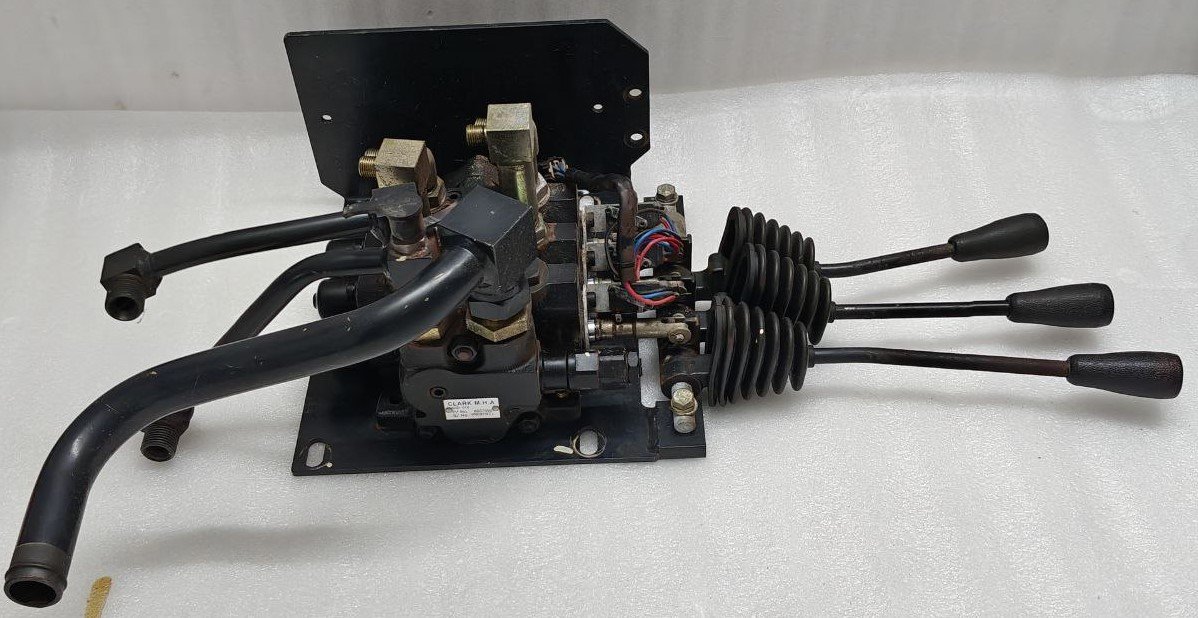

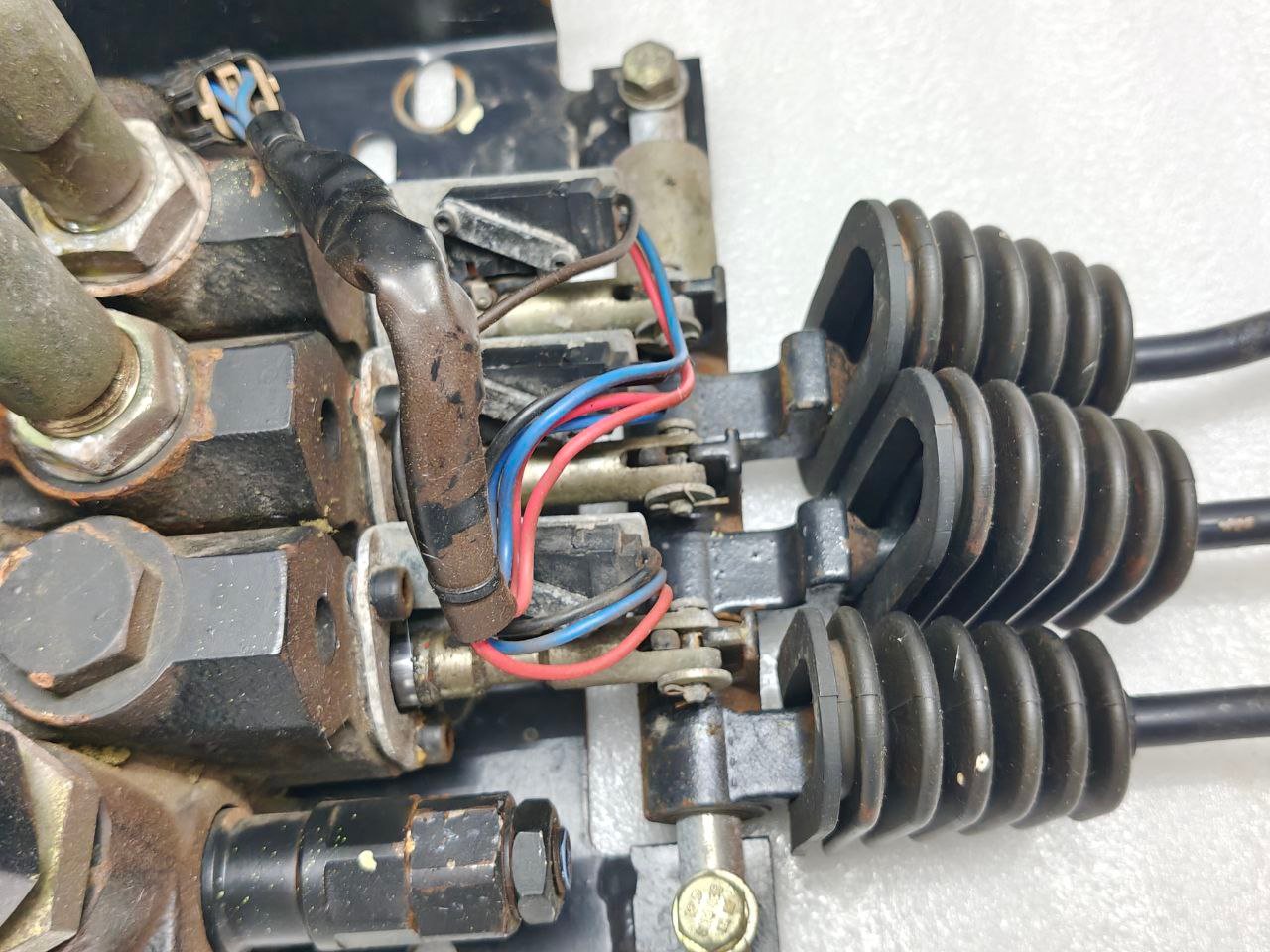

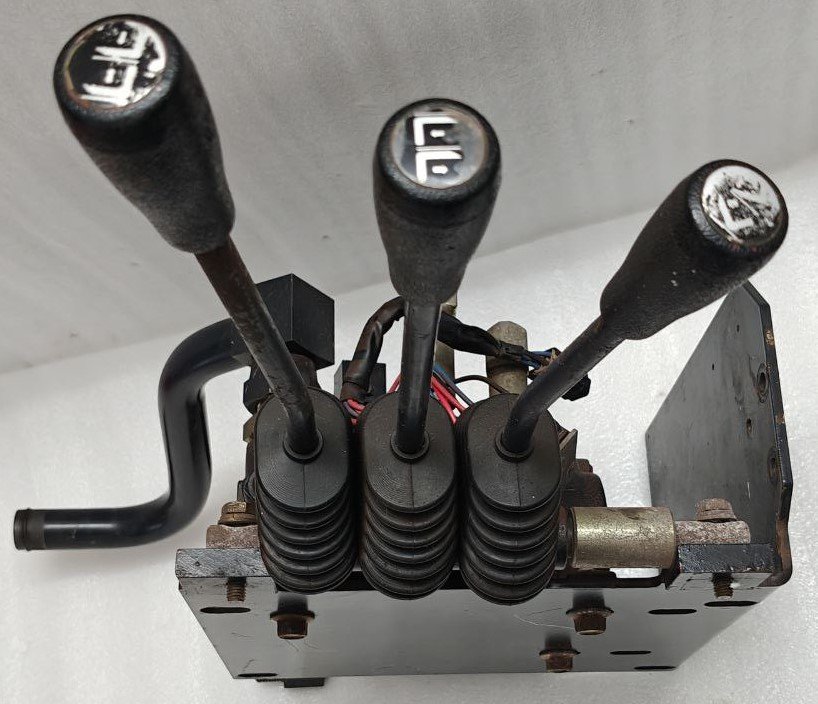

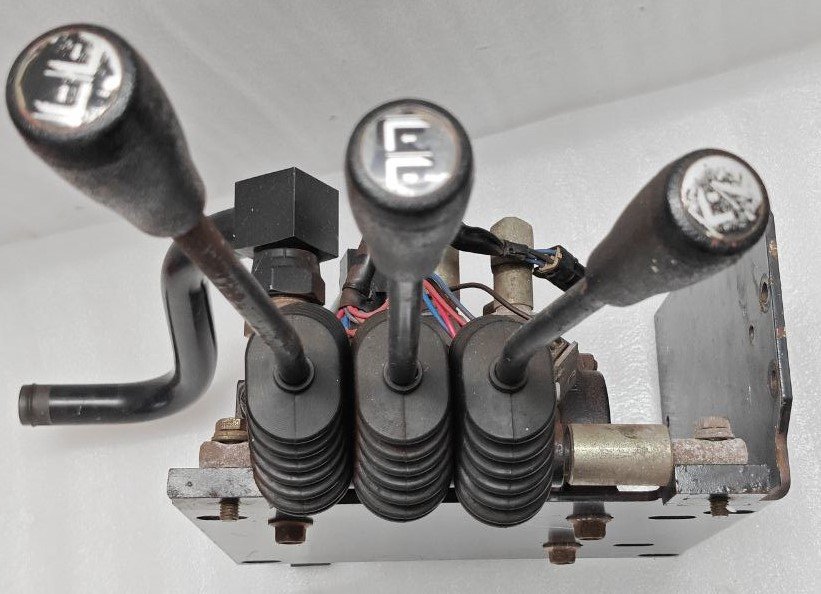

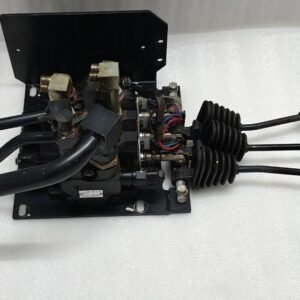

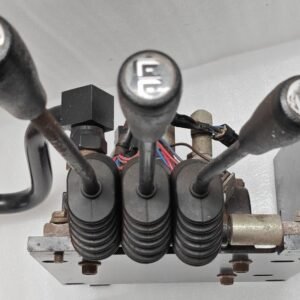

CLARK MHA SCD-010 P NO 8067890 SN 2031 HYDRAULIC CONTROL VALVE FOR FORKLIFT 11:08

$1,510.00

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

Product Type: Hydraulic Directional Control Valve (Lever Operated)

Primary Function:

This valve is the main control unit for the hydraulic functions of a forklift. It directs the flow of pressurized hydraulic oil from the pump to various hydraulic cylinders to perform specific actions.

Typical Functions Controlled:

-

Lift / Lower: Controls the main lift cylinder that raises and lowers the forks.

-

Tilt Forward / Tilt Backward: Controls the tilt cylinders that angle the mast forward and backward.

-

Side Shift / Auxiliary Function (if equipped): Many forklifts have a third or fourth spool for additional attachments like side-shifters, carton clamps, or rotators.

Key Features & Characteristics:

-

Monoblock Design: The valve body is typically a single, solid block of cast iron or aluminum, making it robust and leak-resistant.

-

Lever Operated: The operator uses mechanical levers linked to the valve spools to control its functions.

-

Open Center System: Most common in forklifts. When no functions are activated, hydraulic oil flows freely through the valve back to the reservoir, minimizing heat build-up and energy consumption.

-

Parallel Circuit: All valve sections (spools) receive pump flow simultaneously, allowing for combined functions (e.g., lifting and tilting at the same time), though the function with the least resistance will move first.

-

Built-in Relief Valve: Protects the hydraulic system from damage by limiting the maximum system pressure.

-

Load Check Valves: Internal valves that prevent a load from dropping unexpectedly if a hose bursts or a connection fails.

Common Applications:

This specific valve is designed for use on Clark brand forklifts. It would be found on various electric and internal combustion (IC) pneumatic tire forklifts within Clark’s product range.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.