- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

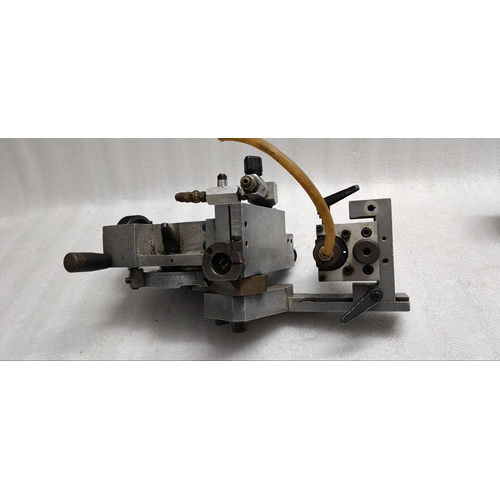

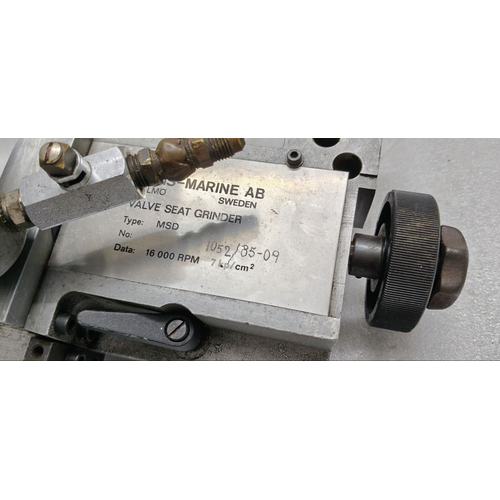

CHRIS MARINE MSD Engine Valve Seat Grinder Grinding Machine, Air Driven

₹83,361.00

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

CHRIS MARINE MSD Engine Valve Seat Grinder Grinding Machine, Air Driven

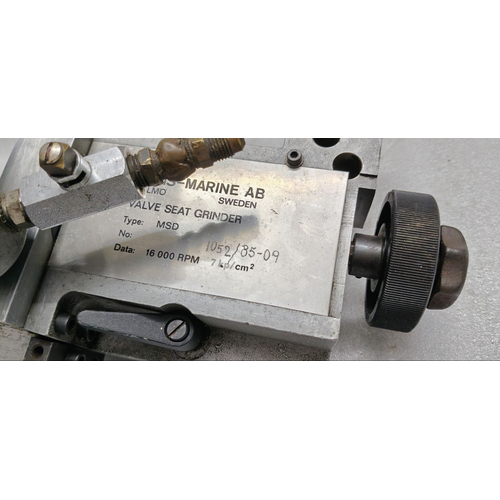

Chris Marine Valve Seat Grinder Type MSD 16000 RPM

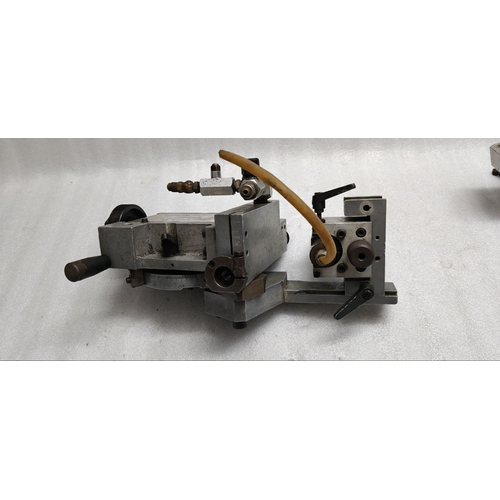

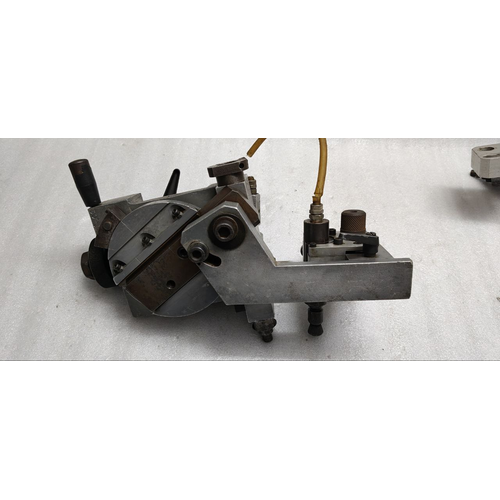

The CHRIS MARINE MSD Valve Seat Grinding Machine is a professional, air-driven tool engineered for the precise reconditioning of valve seats in large bore diesel engines. Trusted by shipyards, power plants, and engine workshops worldwide, this robust grinder ensures perfect sealing surfaces, restoring engine compression, efficiency, and operational reliability. Its air-driven operation makes it intrinsically safe for use in hazardous environments, while its durable construction guarantees long-term performance under demanding conditions.

Key Features & Benefits

-

Air-Driven Motor (Pneumatic):

-

Benefit: Ensures safe operation in potentially explosive atmospheres found in engine rooms. Provides high power-to-weight ratio, smooth operation, and variable speed control for optimal grinding finish.

-

Keywords: Pneumatic grinder, air-driven tool, explosion-proof, safe operation.

-

-

Precision Grinding & Accuracy:

-

Benefit: Designed to achieve a perfect, leak-free seal between the valve and its seat. This restores engine compression, improves fuel efficiency, and reduces emissions.

-

Keywords: Precision grinding, accurate valve seat, leak-free seal, restore compression.

-

-

Robust & Durable Construction:

-

Benefit: Built with high-quality materials to withstand the harsh, corrosive marine environment and the rigors of daily workshop use. A long-lasting investment for your maintenance toolkit.

-

Keywords: Marine-grade, durable, heavy-duty, long service life.

-

-

Ergonomic & User-Friendly Design:

-

Benefit: Lightweight and well-balanced for reduced operator fatigue. Simple controls allow for quick setup and efficient operation, minimizing maintenance downtime.

-

Keywords: Ergonomic design, easy to use, reduced operator fatigue.

-

-

Compatibility with CHRIS MARINE System:

-

Benefit: Part of the comprehensive CHRIS MARINE valve repair system. Can be used with a range of accessories and pilots for grinding various valve seat angles and engine models.

-

Keywords: Chris Marine system, compatible, versatile application.

-

Technical Specifications

-

Drive Type: Pneumatic (Air-Driven)

-

Operating Pressure: 6-7 bar (85-100 psi)

-

Air Consumption: Approx. 300 l/min

-

Speed: Variable, depending on pressure and load

-

Weight: Lightweight and manageable for precise control (exact weight depends on model)

-

Connection: Standard industrial air hose fitting

-

Application: Reconditioning of valve seats on medium and large bore diesel engines.

Applications & Ideal For

This valve seat grinder is an essential tool for:

-

Marine Engineers: Performing in-situ maintenance on ship main and auxiliary engines.

-

Power Generation: Servicing large diesel generators in power plants.

-

Engine Repair Workshops: Specializing in the overhaul of diesel engines for industrial, marine, and locomotive applications.

-

Preventative Maintenance Programs: Ensuring engine valves are serviced to OEM standards, preventing catastrophic engine failure.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.