- AUTOMATION EQUIPMENT

- DIGITAL CONTROL

- ELECTRICAL ITEMS

- AMPLIFIER & UPS

- BATTERY CHARGER & INVERTER

- CIRCUIT BREAKER & BLOCKS

- CONTROL UNIT

- ELECTRIC CONTROLLERS

- FIRE ALARAM SYSTEM

- FUSES & CAPACITOR

- HEADPHONE & SPEAKER

- HMI & DISPLAY

- MISC ELECTRICAL

- PCB

- PLC SYSTEMS

- POWER SUPPLY

- PRINTER & CPU

- RELAY

- SENSORS

- SERVO DRIVES & MOTORS

- TELECOME & COMMUNICATION

- THERMOSTAT

- MACHINERY

- SENSORS

- UNCATEGORIZED

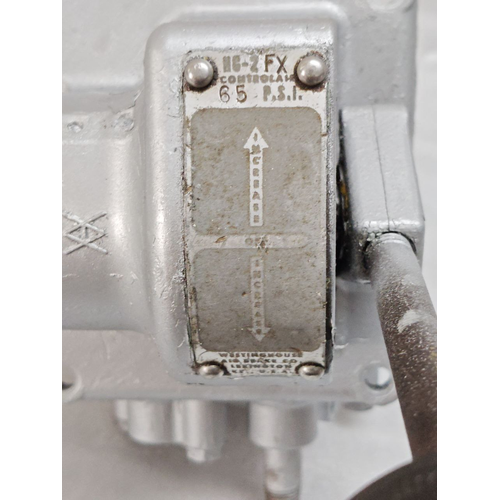

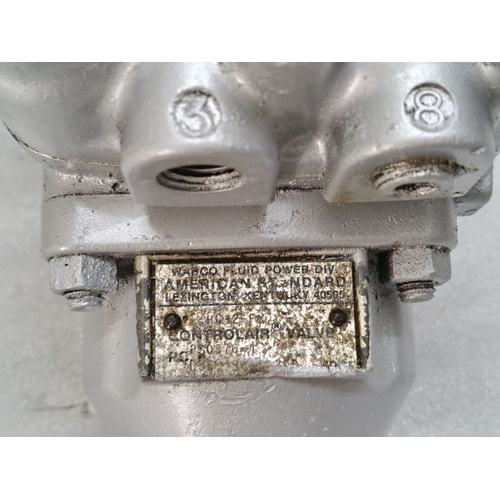

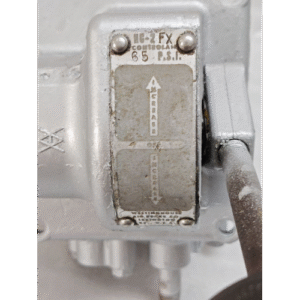

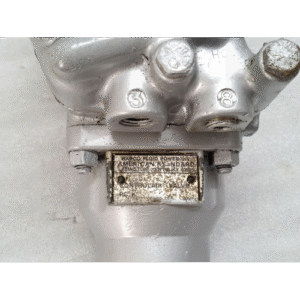

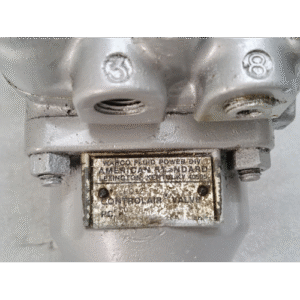

Rexroth HC-2-FX Lever Operated Control Air Valve R431002839 65 PSI 40505

₹17,135.00

| Product Conditioned | USED |

|---|

Free Shipping apply to all orders over $199

Guaranteed Money Back in 30 days return.

24/7 Customer Support

Share:

Hotline Order:

(+101) 5620 - 8155

Email ID:

xstore@support.com

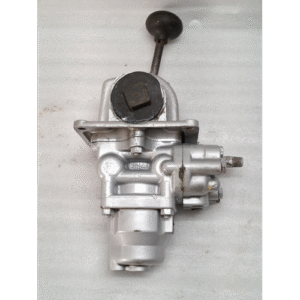

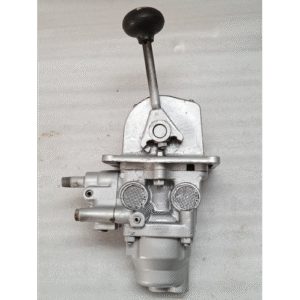

The Rexroth HC-2-FX is a robust, high-performance, 5/2-way pneumatic directional control valve designed for precise manual control of air circuits. The “Lever Operated” mechanism allows for quick and positive actuation, making it ideal for applications requiring direct manual intervention, such as setup, testing, maintenance, or emergency control. The part number R431002839 is a specific configuration of this versatile valve family.

The valve is engineered to the high-quality standards expected from the Bosch Rexroth brand, ensuring reliability and long service life in industrial environments.

Key Features & Specifications

| Feature | Specification |

|---|---|

| Manufacturer / Brand | Bosch Rexroth |

| Model Series | HC-2 |

| Valve Type | 5/2-way, Mono-stable (Spring Return) |

| Actuation Type | Lever Operated (FX) |

| Part Number | R431002839 |

| Port Size | 1/4″ (Typically G1/4 or NPT1/4) |

| Operating Pressure | 65 PSI (0.45 MPa / 4.5 bar) – This is the standard operating pressure. |

| Max. Operating Pressure | Typically up to 150 PSI (10 bar) for the HC-2 series. Always confirm with the specific datasheet. |

| Return Mechanism | Spring return to the initial position when the lever is released. |

| Position | 2 positions, 5 ports (5/2) |

| Standard | Conforms to CETOP RP 52 P and ISO 5599-2, ensuring interchangeability. |

| Mounting | Sub-base or manifold mounting (conforms to ISO 5599-2 interface). |

| Material (Housing) | Typically corrosion-resistant metal like brass or aluminum. |

| Seals | Nitrile (NBR) standard, suitable for lubricated or non-lubricated air. |

Function and Operation

-

5/2-Way Function: This valve has five ports (1 – Pressure In, 2 & 4 – Actuator Ports, 3 & 5 – Exhaust Ports) and two distinct positions.

-

Lever Actuation: Moving the lever manually shifts the valve’s internal spool from its spring-centered “home” position to the second actuated position. This changes the flow path of the compressed air.

-

Spring Return: When the operator releases the lever, the internal spring automatically returns the valve to its original default position. This “fail-safe” or “home” function is critical for many control sequences.

-

Flow Path:

-

Position 1 (Resting): Supply air (P) is connected to one actuator port (e.g., A), while the other actuator port (e.g., B) is connected to exhaust (R).

-

Position 2 (Actuated): When the lever is pulled, supply air (P) switches to the other actuator port (e.g., B), and port A is connected to its exhaust (S).

-

Typical Applications

This valve is commonly used in industrial automation and machinery for:

-

Manual Override: Providing manual control for automated systems during setup, troubleshooting, or in case of power failure.

-

Jogging and Setup: Precisely moving pneumatic cylinders or actuators during machine calibration and program teaching.

-

Safety and Maintenance Functions: Acting as an isolation or control valve for lockout-tagout (LOTO) procedures or safe maintenance cycles.

-

Control Panels: Installed on operator stations for direct control of specific machine functions.

-

Testing Equipment: Used in pneumatic test benches and fixtures.

We're here when you need us

Get a Quick Quote

Complete our online form.

Call US

Speak to one of our team.

Live Chat

Send us a message

Speak to one of our team.